RCN Reviews: Baileigh TN-250 Tube Notcher

By Dean Larson

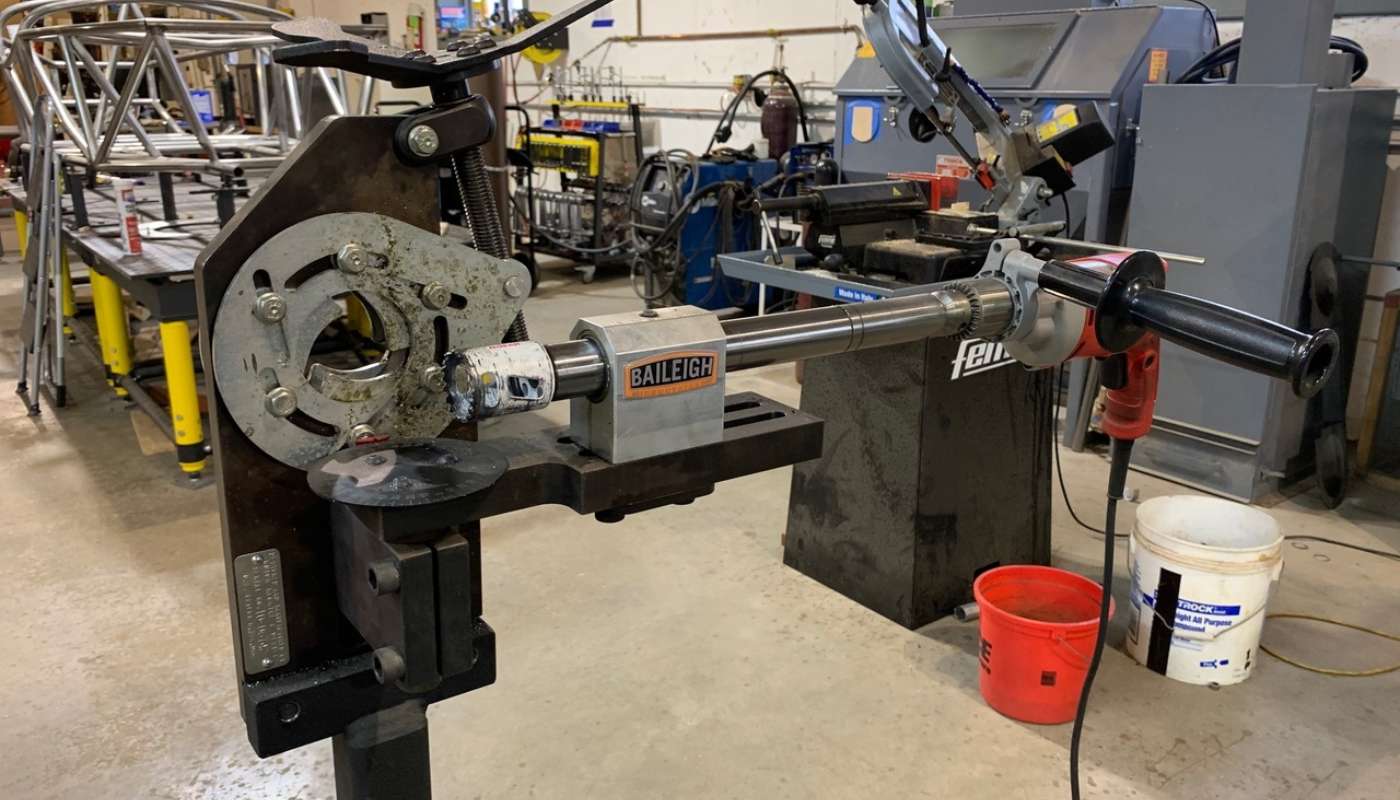

There are plenty of tubing notchers on the market if you’re looking for a light-duty, bench vise-mounted unit, and there are great self-powered notchers on the market if you’re looking to spend a few thousand. For our purposes, we wanted a dedicated tool that could handle tight cuts and complicated pieces on a frequent basis — a tough and capable unit without shelling out big bucks for a commercial-grade piece. With that in mind, we went with Baileigh’s TN-250 tube notcher on a permanent floor pedestal, a setup we’ve been using for roughly two years now.

Like other tools in its class, the TN-250 is a hole saw type notcher that requires the use of a corded drill and hole saw bits. Baileigh’s tool can either be clamped into a vise, bolted to a table, or fastened to a dedicated floor pedestal as ours is. It accommodates tubing up to 2.5-inch O.D. and pivots 220 degrees, allowing you to access the backside of a notch cut. The whole carriage can also be moved up and down, allowing you to offset a notch up to 1 inch. The tool’s party piece is probably its clamping system though, a self-centering vise clamp that will grab onto a tube pretty much anywhere, even in the middle of a bend. The drill hangs off a 1.25-inch Thompson shaft, which is fit with sealed needle bearings.

Used for chassis fabrication on a regular basis, we’ve had a chance to put this tool through its paces, and it’s held up really well. Ours is setup with a 1/2-inch, 8 Amp Milwaukee corded drill and a bolt-on floor pedestal from Trick Tools, which allows the most room to work in our opinion as compared to bolting it to a table or using a vise. The tool has performed flawlessly, but it’s worth noting that you need to go slow and let the tool do the work. Get too anxious and you’ll rip a tooth out of your bit, giving the operator a bit of a jolt. Also, a little cutting oil goes a long way. Like any of these hole saw-style notchers, there’s going to be some finish work required to get your joints Instagram ready, but this tool is going to get you 80-90 percent there.

Choosing the right notcher for your shop is all about knowing what you’re going to ask of the tool and how far you can stretch your budget. For our purposes, the Baileigh TN-250 is just right and handles regular chassis fabrication with ease. Our setup cost us right around $1,000 for everything, which is quite a bit more expensive than the basic overseas units, but considerably cheaper than a commercial-grade piece. While a tool is only as good as its operator, we can assure you this piece is more than sufficient for basic and advanced chassis fab and will take you a long way.

Score: ✓+

Comments for: RCN Reviews: Baileigh TN-250 Tube Notcher

comments powered by Disqus