Spools and mini spools for your project car

By Dean Larson

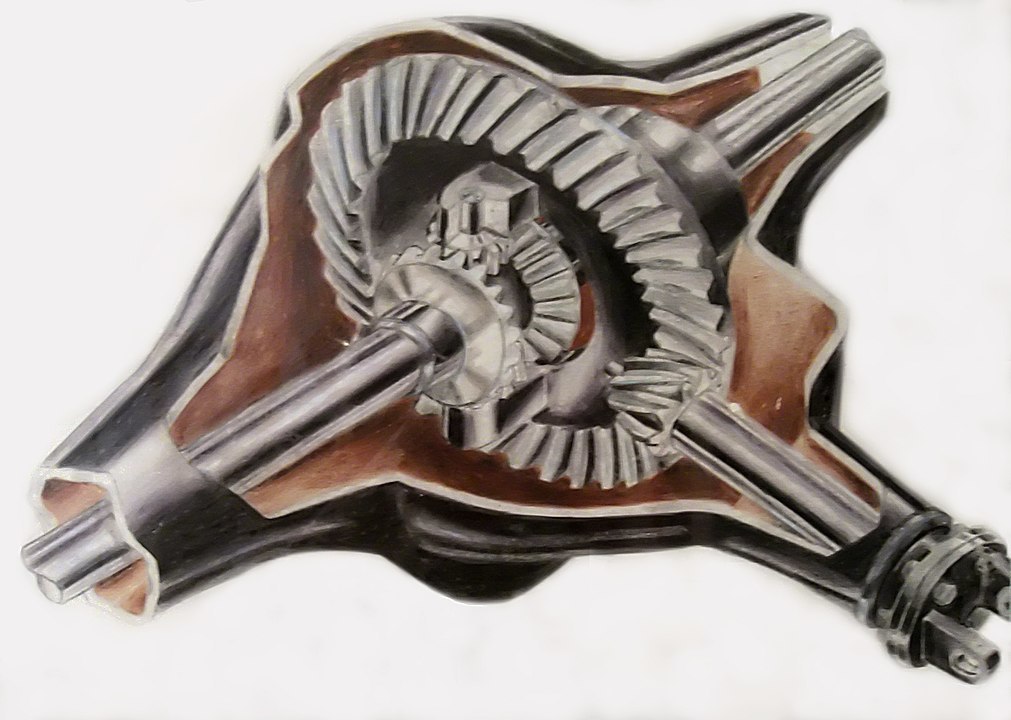

Photos: Dean Larson, Summit Racing and Diagram of a differential between drive shaft and the rear wheels., CC BY-SA 3.0, https://commons.wikimedia.org/...

Whether your road racing, hitting the drag strip or wheeling off-road, the name of the game is traction, and there’s more than one way to play. Some weld their diffs quick and dirty like for instant (albeit risky) two-wheel satisfaction. There are also spools, mini spools, LSDs and several breeds of full lockers. But in the pursuit of getting both wheels spinning, there are methods that are right and wrong, given your budget and the way you’ll use your vehicle. Recently we covered the pros and cons of welding your open differential, since it’s usually the quickest and cheapest way to get both wheels spinning. But that doesn’t mean it’s the right way, so be sure to read our full feature on Lincoln locking — a sort of primer if you will for today’s topic — mini spools.

The best approach for traction in your ride depends on a lot of factors, but probably our biggest concern is if you plan on cornering anytime soon. Because if you do, you want a rear gear set that permits slip, allowing your inside wheel to turn at a slower rate than your outside wheel, which is the whole purpose of your differential to begin with (and the source of the namesake as it were). But there are other times where wheel speed differentiation isn’t as important, like drag racing, off-roading and possibly drifting (I’m no expert there). In these applications, we’re just concerned about putting the maximum amount of power to the ground, equally distributed to both wheels. In these situations, you may elect to weld your differential, or to install a spool. While both methods accomplish the same ends, there are several key advantages to a spool, as we’ll see. But first we need to discuss and differentiate the two types of spools — full spools and mini spools.

Mini Spools

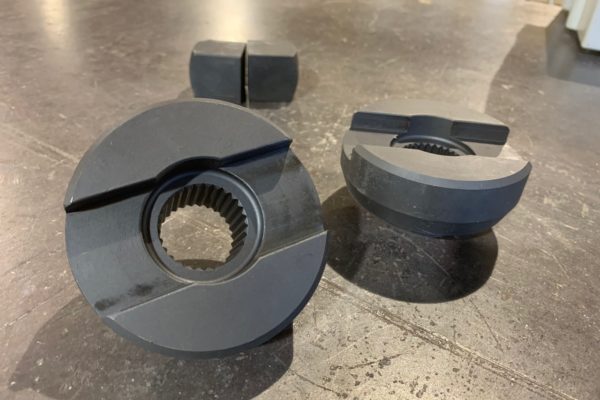

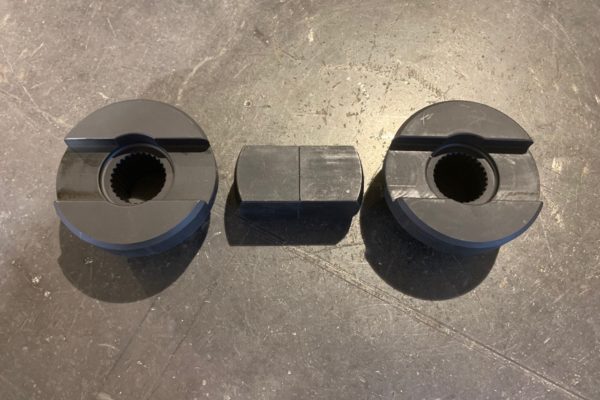

We’ll start with mini spools, because these are the easiest to install and simple to understand after you’ve mastered the finer points of a welded carrier. Your typical mini spool replaces the differential side gears and spider in an open carrier with blocks that are held together tightly by the carrier pin. The pin goes through the center blocks that fit tightly into slots in the replacement side gears. This ensures that the whole assembly works as a single unit, and power is distributed equally to both sides.

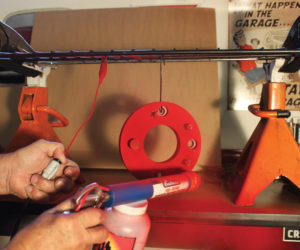

To spec out a mini spool, you’ll want to know exactly what axle you have in your vehicle, as well as the exact spline count of your axles. Ease of installation is one huge positive over the full spool, as you’re not messing with the gears or bearings at all. Simply pull the cover, drain the fluid, clean out the axle and remove the pin, side gears and spider gears. Then you install the new side gears, center blocks and pin, and you’re ready to rock. In most applications, you’re probably reusing your side gear shims, so keep track of those when you disassemble it.

Mini spools work pretty well and are generally inexpensive to purchase, but there are a few things to keep in mind. To start, the spool is going to put extra strain on your stock axles, especially if you plan on doing any cornering, so it’s worth knowing the limits when you start. We’ve also seen a lot of guys say that their mini spool didn’t fit without some modification, presumably due to side gear shim thickness, so be prepared to do some problem solving on that front. It’s worth repeating that these units will only work with open differential carriers, so know what you have before you enter those credit card digits.

In many applications you can get a mini spool installed in your car for $100 or less, and there are a ton of great options out there from Yukon Gear, Motive Gear, Richmond and more. You’ll have power to both wheels, and the carrier can handle more abuse since there are fewer moving parts. And unlike the ’ol Lincoln Locker, you can easily remove the mini spool if you don’t like it.

Full Spools

A mini spool works well for many weekend warriors, but as horsepower goes up, you’re going to want something stronger, lighter and more purpose built. That’s when you’ll want to look at a full spool.

A full spool replaces the entire differential carrier, with the axles sliding into each side and the ring gear bolting directly to it. It checks the boxes for strength and lightweight, and is the choice for many drag racers because. The spool is designed to handle more power than your stock carrier, as it’s a single piece, and will handle much more abuse than a mini spool as well.

Full spools are also a low-cost option when compared to lockers or performance LSDs, and you can pick up decent units for most applications for less than $200. The main factor to consider when installing a spool is that you’ll have to set up your bearings and gear mesh pattern, unlike the mini spool. For many of us that’s no sweat though, and there are plenty of instructional videos and articles out there.

Many of the same installation concerns are shared between the spool and mini spool, mainly that you’re not going to want to use one of these on the street. Sure, I know your buddy drives his Nova on the street with a spool all the time, but we obviously cannot condone that behavior. But if the strip is your main concern, a nice heat-treated stainless steel spool and some chromoly axles could be just the ticket.

So if you want to save a couple bucks over, say a Detroit Locker (which can run you around $600), a spool or mini spool could be what you need in you drag car or off-road rig. Stick around for our next Traction 101 segment when we dive into the world of limited-slip differentials, and remember, "... it just does."

Comments for: Differential Spools 101

comments powered by Disqus