Composite Materials for the Car Builder

Story by Dan Burrill

Photos by Dan Burill and Courtesy of Cord Bauer, Bauer Ltd.

While most production cars have bodies made of sheet metal, and only a few use composites, the reverse is true in the replica world. That’s because it’s relatively faster and easier to mold a body out of fiberglass, and far less expensive as well. Given that ReinCarNation focuses on replicas, it only makes sense for us to cover some basics about fabrics, mats and resin, along with some newer, advanced materials such as carbon fiber, including a way it can be handled by the DIY car builder.

Fibers and mat

Fiberglass is made from molten glass that is pulled or extruded through small holes in an industrial furnace, and stretched into fine fibers called yarn. Most fiberglass yarn is called E glass, which was designed originally as a boat and tooling fabric but, of course, is excellent for all parts of automobile fabrication. Although it has been available since the 1940s, it is still the most widely used in the most economical all-purpose composite reinforcement.

The bulk of the glass is woven into fabric. Then a process called chroming is applied to the E-glass so the resin sticks to or blends with the woven glass for a better bond and adhesion.

Which E-glass fabric should you use for a specific application? Fabric selection is based on a number of factors, such as what we are making, how strong it has to be, and how big a factor the weight is. Proper fabric selection is a balance between the required strength in the least possible weight.

For example, a race car needs to be as light as possible, so a fabricator might use 1.4-ounce cloth. However, a motorcycle ramp used to load bikes into a trailer needs maximum strength, so for that project the maker might use 18-ounce roving fabric. As a car builder, you must decide what properties are most important when you make a fabric selection.

Industrial fabrics are available in a wide variety of weights from 1/2 ounce to more than 50 ounces per square yard. The heavier the fabric, the stronger it is, with the heaviest fabrics yielding a breaking strength of more than 1,500 psi. You can also find a selection of weave types to maximize strength and the ability to drape and form the fabric in particular orientations.

Chopped strand or fiberglass mat is a reinforcing material made of loose glass fibers pressed together and held with a binder that is soluble in polyester resin. Mat works well with cloth or roving to increase the bond strength, and when more thickness and stiffness is desired.

A product called surface Veil Mat Ultrathin is used as the first reinforcement next to the gel coat and a molded part to reduce readout or print-through of weave (the visibility of the mat through the gel coat, or finishing layer).

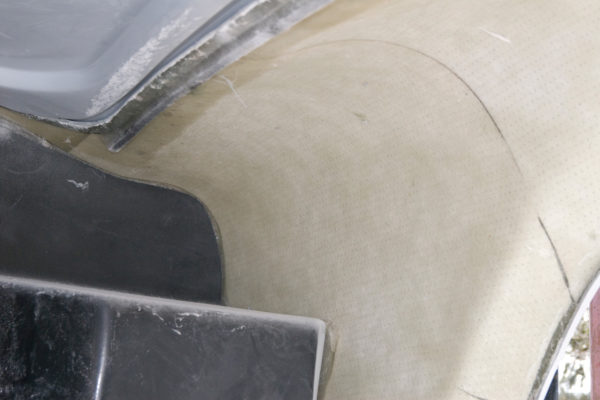

Coremat is a polyester nonwoven material with small holes, and is used as a bulking mat in fiberglass layups, or as the last layer in chopper gun applications. It is used in wheel wells to prevent or cut down on the possibility of star chips, which are caused by pebbles or small rocks thrown up against the underside of the fenders, leaving a star-shaped crack in the top side of the body. The star-shaped crack not only splits the paint, but also penetrates through the fiberglass layers. Coremat doesn’t always work, but it sure helps, and in certain instances it helps cut down on road noise.

Resins and catalysts

There are a wide variety of resins on the market today, each with different characteristics, and designed for different purposes. However almost every amateur who deals with fiberglass auto body construction and repair is probably using one of just three resins, so we’ll focus on that one; polyester.

Resin, when mixed with a catalyst and saturated into fiberglass and other materials composites, transforms the whole sandwich into a hardened state, thus turning the flexible material into a usable product. Once hardened or cured, the new product can be sanded, cut filled, and changed time and again depending on the use required at the time.

Polyester resins are the most used, since it costs considerably less than comparable epoxy resins. Polyester does well for most applications and is used most often while making fiberglass car bodies, automotive parts, and many other applications such as reconstructing old fiberglass bodies.

One important consideration is that polyester resin has some leeway in matching the cure time to temperature conditions, and the required time for the application of the resin. By adjusting the amount of catalysts, you can control the resin working time in the rate of cure.

Methyl ethyl ketone peroxide is the catalyst added to both polyester resins and vinyl ester resins. As the catalyst mixes with the resin, a chemical reaction occurs, creating heat, which cures or hardens the resin. The outer layer cures or hardens first because it is exposed to the air, but the layers underneath take a much longer time to fully cure. For most resins the recommended ratio is approximately 1/2 ounce of catalysts per quart of resin.

Advanced composite materials

When automotive engineers and enthusiasts speak of composites, they are talking about two or three more different materials used together to maximize the benefits of the special features of each individual ingredient. Most expensive is carbon fiber, as a square yard of fiberglass is about 15 percent of the cost of roughly the same amount of carbon fiber.

Carbon fiber and other components are often used instead of fiberglass because they are far lighter and have greater strength. Serious professional shops use dry carbon fiber prepreg, which is a carbon fiber that has been pre-impregnated with the resin laid up in a mold, vacuum bagged and baked in an autoclave to achieve the ultimate in lightweight, ultrathin and structurally sound shapes. But if you just want the carbon fiber look you’ve got some far easier options that you can use.

While some auto parts stores will sell rolls of contact paper that looks like carbon fiber, its not the same and looks cheap. A much better solution is to use some epoxy prepreg carbon fiber sheet which is sticky enough to mold into just about any shape. You should note that the weave has a bias to it and molds better in some directions than others.

TAP suggests using double sided stick tape to attach the carbon fiber to an existing part as an outer covering, and then painting the carbon fiber with a product called Ultra-Glo. This is a two-part polymer-based clearcoat that you can simply pour onto your carbon fiber covered part and let it flow around evenly. This product really makes the weave of the carbon fiber cloth pop and shine. Note however that this product is not UV tolerant, and yellows and cracks over time if you leave it outdoors.

All told, fiberglass is a highly versatile material that can be used in a wide variety of applications, from basic parts to high-tech components. So do some homework before before diving in, and pick the right materials for the job.

Comments for: Composites - Plain and Simple

comments powered by Disqus