Endless perseverance and a Dremel built this GTM

As Told by Tobe Johnson

Great issue Steve! I see you got RumRunner’s Factory Five GTM in there. Awesome! He is a good guy. Did a good job on his car too :)

I’ve been on my own since I was 18 with no financial support and almost no family to turn to. I couch-hopped from place to place to help make it through Junior College while working two to three jobs. I graduated a year early from my local JC with my major course of Mechanical Engineering. I applied to multiple colleges and ended up going to Cal Poly SLO.

While going to Cal Poly my grades suffered with my jobs and full time Mechanical Engineering courses. At this time I was also in an accident (my bicycle versus a car door) and I sheared off my left elbow. After surgery to reattach I was fine until five months later I snapped it off again during rehab.

Fast forwarding, I got kicked out of Cal Poly due to poor grades and missing finals while in the hospital for the elbow incident (professors would not let me make up my finals). I worked multiple jobs still and took some classes at another JC. I later got a job working as an Aerospace Machinist. Some notable jobs I worked on was the actual machining of the titanium legs and pivot joints that are currently on the Mars Rover Curiosity as well as other parts for the James Webb Space Telescope.. and much much more.

During that job I managed to fight to get back into Cal Poly and finish my Bachelors in Mechanical Engineering as well as three associate degrees in math and Science, Physics, and Engineering. I now work as a Rocket Launch Engineer (Mechanical Systems) for SpaceX.

Now for the GTM.

At my first career job, post graduation, I served as Design Engineer to Project Engineer at Zodiac Aerospace. While there, I watched a video on Yahoo about some kit car called the Factory Five GTM being compared to a McLaren MP4-12C. I watched the short video and immediately knew I was going to buy and build that car.

Of course, the amount mentioned to build the car is a lot less than the true amount—unless you happen to have all parts on hand. I did my research prior and realized the most likely cost of my wants before buying. I have had some experience working on my previous cars (‘93 Toyota Supra TT, 05 EVO 8 MR, ‘07 Roush 427R, ‘91 Eclipse GSX, ‘95 Eclipse GSX, ‘02 Celica GT). I got the personal loan and bought the kit and then the donor parts, engine, and transaxle, along with countless other miscellaneous nuts and bolts I needed for the build. Oh, and I needed tools too.

I own my house which is a major help and almost a necessity to build a kit car. I took delivery of the kit on February 15, 2013 at 1pm. After unloading the boxes and body panels, I spent two days smiling, and then got to work.

Another setback: On March 13, 2013, I was on my way to work on my 2012 Hayabusa and was T-boned by a fully loaded semi at about 30mph, per the police report. I was forced to go to the ER in the ambulance. I ended up ripping off the left side of the titanium/carbon fiber racing exhaust with my leg, since the exhaust was pinned between my bike and the semi (and my leg). I checked out OK somehow, with only bruises from left knee down. I called one of my design engineers to pick me up out of the ER, while this whole time thinking, “My poor bike” and “How will this effect me finishing the GTM?”

My engineer picks me up, takes me to my house so I can change into new pants that aren't shredded. I go back to work and hobble around for six hours. I then have a friend take me to the tow yard, I pay for my bike and with exhaust in hand I ride it out to his truck and take it home. The next day I worked from home and then went into my garage and continued work on my GTM. I propped my leg up in the air while I worked on paneling underneath it.

As a Project Engineer I averaged 50- to 60-hour work weeks. Every single day after work I would put time into the GTM. I would spend anywhere from two to 16 hours a day on the car. I did all the work, except for the paint job and window install. I learned how to do fiberglassing from a friend/coworker of mine. I also got quick tips from another friend/coworker on the electrical portion.

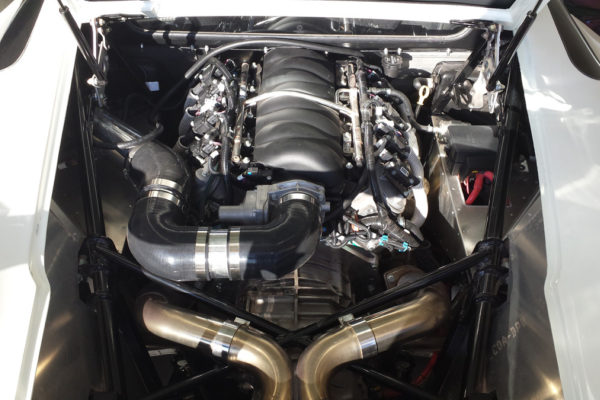

I purchased my crate motor (LS376/480) and harness from Jegs Performance. The transaxle (G50/20 six-speed w/ LSD) was purchased from a forum member. My donor parts all came from Ebay, purchased from a junkyard company. My exhaust, Kooks, was purchased second-hand, unused. I wrapped the headers with DEI VR wrap, up to the collector. I made a custom four-inch CAI (cold-air intake), following a similar design done by another forum member.

I took the GTM for its first go-kart ride on February 15, 2014 at 12:30pm—almost exactly one year to the hour. One month later it was fully finished, with the painted body and windows installed. The car has a fully functional roof scoop, side scoops, and radiator vents. Everything looks as if it came out of a factory. I have taken the car to the SLO Concours, entered, and won People’s Choice: Best Sports Car. I was invited by Dave Smith at Factory Five Racing to bring my GTM to SEMA to represent FFR. Unfortunately my space was taken up by their new 289 FIA.

One thing to note. I built roughly 80 percent of this car with a single low-end Dremel tool. It was 100 percent built in my two-car garage, which also houses my Hayabusa motorcycle, three bicycles, tools and storage, and XL dog pen. One more thing, I almost forgot to mention that the cost to build this GTM with all labor done by me: $75,000. Sense of accomplishment from perseverance: priceless!

Comments for: PRICELESS PERSEVERANCE

comments powered by Disqus