Track-prepped Factory Five 818R

Story and Photos by Steve Temple

Modifying cars, trucks and bikes has always been an opportunity to express personal creativity and innovation, but component cars are arguably the greatest form. Your creation starts life as nothing more than a package of parts, and it’s a total blank canvas for the builder’s art.

A prime case in point is Ray Pasquetti’s 818R. A general engineering contractor by profession, he’s constructed a couple of custom Cobras and several drag boats over the years. But on his 818R, he really pulled out all the stops by working the numbers, giving it a radical power-weight ratio, similar to his lightweight Emerson Motorsports Cobra. Why so?

“I built the 818R to whip my son’s butt in the Cobra that we still race,” Ray notes. His son Jason’s competition-spec Cobra replica has a thin skin and frame, so it tips the scales at just 1,900 pounds. Not only that, but it’s powered by a 4.6-liter Ford Aluminator boosted by a Kenne Bell Mammoth twin-screw supercharger. At 11 pounds of boost, power output is somewhere north of 600 hp. This car is so quick, it beat the track record at Thunderhill awhile back.

By comparison, Ray’s 818R weighs about 100 pounds less and delivers 350 hp. A much higher output is easily attainable, though, given that the boost is set at only 7 pounds thus far. Ray says he could dial it up to 17 pounds, good for more than 500 horses. “But the engine won’t live,” he points out.

He also points to a potential for oil starvation on big sweeping turns, as all the engine lubrication flows into the one side. Even though its power-weight ratio is not as extreme as the Cobra’s, it has other advantages for road racing, as we’ll see.

The 818R project took about three years, 5,000 hours of labor and $65,000 in coin. The list of components he incorporated goes on for days, so we’ll try to hit the highlights instead to illustrate our initial point about creative expression.

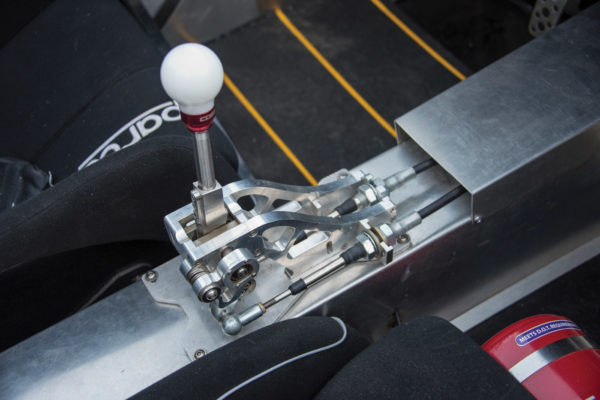

The donor car was a 2007 Subaru WRX that cost $5,700, but it provided only a few parts. “I only used the steering column, rack-and-pinion, engine and transmission,” he points out. He later swapped out the factory lump for a built STI engine, as he wanted a stronger setup.

The engine was substantially reworked by FW Motorsports, using a nitrided crank rotated by Manley Performance H-beam rods and Wiseco 100 mm pistons with ACL race series bearings. Boosting the output is a heat-shielded Blouch turbo (a Dominator 1.5XT-R) fed by a Cobb Tuning short-ram SF intake with an AMR Performance cast-aluminum inlet and controlled by a GrimmSpeed solenoid (electronic blow-off valve).

To keep up with the higher airflow from the forced induction, MagnaFuel supplied a QuickStar 300 fuel pump and EFI pressure control unit, running through Cosworth fuel racks and Injector Dynamics 1,000 cc nozzles. A Very Cool Parts air-to-water intercooler improves air density to optimize the burn. On the exhaust side are ceramic-coated Perrin equal-length headers.

Keeping this blistering mill from overheating is a KOYORAD aluminum racing radiator with a pair of Mishimoto shrouded fans. Transferring the engine output to the transaxle is an EXEDY organic clutch and lightweight flywheel.

Ray admits that Jason’s Cobra could best his 818R in the straights, but not in the twisties. Here’s where weight balance has its advantages. Since the 818R has a midengine setup, it’s a primo corner carver.

“The Cobra can’t keep up with my 818 in the turns — the car flies,” he beams. “It’s balanced so much better. It just sticks.” That’s in marked contrast to the nose-heavy Cobra’s tendency to throttle steer, spinning the tires loose as it drifts around the apexes. This old-school style of handling can be way fun, but the G-forces are so much higher on the 818R that “I had to get a full containment seat to stay in it!” he exclaims.

Achieving such a tight suspension required some extra custom work on his part, yet another expression of creativity. He notes that the Factory Five Racing manual covers the street version of the 818 in detail, but for building a racer, “You’re pretty much on your own.”

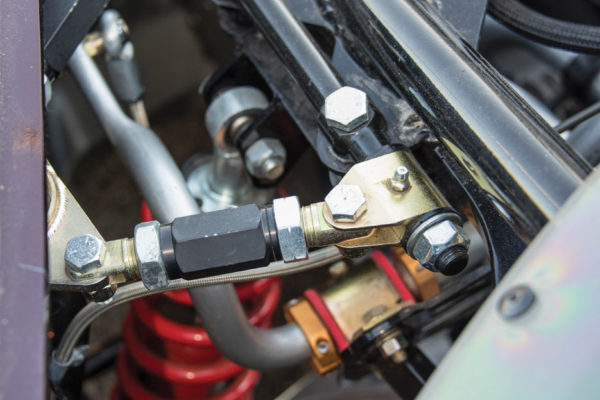

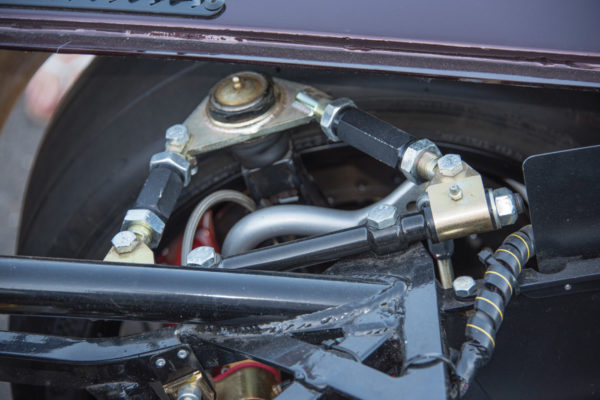

Relying on trial and error, he added custom SuperPro polished aluminum lower control arms and Godspeed’s rear lateral links and trailing arm setup with adjustable turnbuckles. Ray set his Eibach coilover shocks at 400 pounds upfront and 650 pounds in the rear. Brakes are Wilwood Dynapro units (six-piston front, four-piston rear), and the chassis is fitted with a Baer Brakes bump steer kit.

Ray is still sorting out the suspension and trying to add more caster to the front end. In the meantime, the body went on a high-fiber diet, as he added loads of carbon components supplied by Factory Five. Ray also worked in a two-tone color scheme with burgundy rose and matte silver.

The result earned him a Best of Show trophy at Factory Five’s Huntington Beach Cruise-In. Now all he has to do is whip his son’s Cobra road-course record and get a track trophy as well.

Comments for: Numerical Advantage

comments powered by Disqus