Factory Five and Summit Racing Cobra Project

Text and Photos by Steve Temple

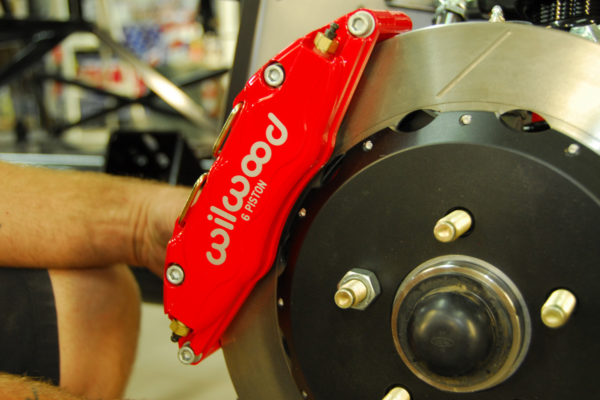

Even though Summit Racing chose a Sixties-style Cobra replica as a project car, dwelling on the past was not a primary consideration. While this ride has all the sound and fury of a classic muscle car, it also displays decades of development in automotive technology. Everything on the chassis, from the frame rails to the custom suspension to the Ford 427 stroker V-8, all of these components are engineered for improved performance and long-term durability. They’re also readily available from Summit Racing and Factory Five Racing (FFR) for ease of construction.

In this series of articles on the buildup done at SKJ Customs, we’ll be providing hands-on tech tips that show how simple and affordable it can be to build your very own contemporary classic, a performer that features both the style of an original and the technology of the latest street machines. Stay tuned for upcoming installments, because once we’re all done, you’re in for one wild ride!

Chassis and Suspension, Part 1

Starting with the foundation, one quick look at the Factory Five Racing’s Mk4 frame tells you that this ain’t your old man’s Cobra. FFR’s four-inch round-tube main rails have thicker walls (0.120 versus 0.095 inches) than the original, and a backbone section and extra perimeter tubing doubles its torsional rigidity. The dash/cowl hoop is welded to this structurally stronger frame via a cockpit surround cage, as are the hinges for the hood, doors and trunk. Safety enhancements include a taller, stronger rollbar, along with triangulated bracing, side-impact bars and crumple zones.

Add to this setup CNC-cut aluminum panels for lining the cockpit, trunk, and engine bay. These panels, made of 6061-T6 aluminum, are stiffer than traditional 4000-series aluminum, and backed by an integrated matrix of steel tubing for bracing and support.

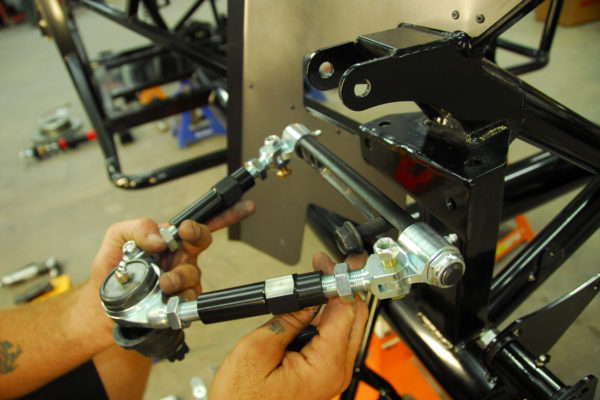

For Part 1, in the accompanying photos and captions, we’ll focus on installing the front suspension and steering rack, and then move to the rearend in Part 2. Final chassis tuning and scaling will be covered at the end of this series, after we show details on the engine assembly and drivetrain install, along with body prep and finish details. Then we’ll head out for some driving fun!

Comments for: SUMMIT MEETING

comments powered by Disqus