Clutch tech for increased power

By Sam Logan

Photos by Sam Logan & Ted7

Smoldering, ruined clutch parts often result from increases in engine power without similar increases in clutch power. It’s a given that a clutch system must possess sufficient clamping force to transmit the additional engine power without slippage. In addition, for street use, operating a clutch should require no more than moderate pedal pressure to operate it, and demonstrate smooth action as well.

Even new clutch-flywheel upgrades can fail prematurely, though, and sometimes immediately, if exposed to abusive conditions — usually at the drag strip. Fortunately such conditions are easily identified and can be avoided. What follows are a few tips on how to dodge clutch troubles under hard acceleration, plus additional pointers on clutch selection and other variables that can affect your choices.

First, while traction control is not often seen on most replicas, some later-model donor cars might be so equipped. If that’s the case, disable the traction control to eliminate the risk of introducing extreme loads to the clutch system. Some traction control systems apply the brakes, while others use rapid ignition retardation that affects the clutch.

Next, select a low gear rather than first. Even professional racers launch in second or even third gears.

Also, when using a water box, ensure the rear tires are positioned in the water during burn-out. As you exit the wet surface, depress the clutch pedal before they reach the dry track. Following this advice protects the clutch system and drivetrain from abrupt and severely damaging forces.

Lastly, when you release the throttle pedal at the finish line, depress the clutch pedal at the same time and keep your foot on the pedal as the car slows. Leave the car in high gear and keep the clutch disengaged until you stop.

If the clutch pedal is not depressed during braking, tremendous load reversals are exerted throughout the engine — particularly the connecting rods — transmission input shaft, driveline and clutch. In fact, excessive deceleration forces are so destructive they can break the drive straps on diaphragm-style clutches. Though stress reversals are less threatening to race clutches, (a Long-style or a billet setup), severe deceleration forces still pull ruthlessly upon the clutch disc hubs and input shaft.

What’s involved in selecting the right clutch? The first two clutch options — the single-disc and dual-disc systems — are versatile choices, since they operate well on both the street and drag strip.

Single-disc clutches transmit significant power, but as power increases, driveability decreases. At 650 hp, most single-disc units have reached their limits and switching to a dual-disc arrangement is advisable.

The dual-disc maintains greater holding power and demonstrates smoother engagement. If your vehicle is devoted to drag racing rather than street driving, select a metallic friction disc. As one example, Ram Clutches offers a 900 series that withstands heat and abuse better than the organic alternatives.

But finding the right balance between friction and slippage is a compromise that comes down to friction material and disc design. “Materials like metallics that have a higher coefficient of friction increase the holding capacity of the clutch as well as its ability to withstand heat under punishing conditions, such as at the dragstrip,” notes Mike Norcia of RAM Clutches. “We can keep the clamp load and pedal effort lower using these materials, but the trade-off comes in driveability, as they tend to engage more aggressively and chatter on takeoff.”

While high-friction discs can increase holding capacity, they also might decrease clutch longevity. With a more aggressive bite, they perform well for a time, but wear out sooner. On the other hand, a less aggressive material will likely last longer, but requires a higher clamping load to perform as well. Increasing clamping load can be achieved with a different disc design. Instead of a a traditional full-face clutch disc, a puck-style design can increase torque capacity and heat resistance.

“Although it sounds backwards, decreasing the friction material surface area through the use of pads or smaller facings actually increases the holding pressure in the clutch,” Norcia points out. “This [change] achieves more holding power, but at the expense of driveability, as these types of facings are generally metallic and engage more aggressively.”

It all comes down to the physics of pressure. A larger surface area spreads out the loading, while a smaller area concentrates pressure. You could roughly compare it to lifting up a car with a small pad on a floor jack, versus putting a larger block of wood between the pad and the car’s frame. This difference in pressure dissipation demonstrates the difference between a full-face and a puck-style clutch.

Increasing clutch diameter increases torque capacity, but the downside is greater rotating weight. Depending on a car’s use, rotating weight can be either an advantage or a detriment. A lighter, smaller-diameter clutch is better for drifting, autocrossing or road racing, where the engine accelerates and decelerates quickly. Less rotating mass allows the engine to decelerate more quickly, so you can drive deeper into corners and brake more aggressively.

Even so, a decrease in clutch size will require more discs to compensate for the reduction in surface area. On the other hand, a larger diameter clutch with more mass and inertia is better for driving on the street, as it doesn’t have to be slipped excessively to get the car moving.

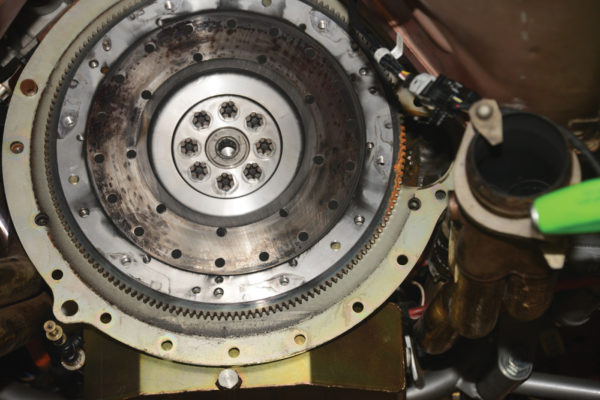

Two other types of clutches, Long-style and billet, are designed chiefly for drag racing. Typically used on race vehicles generating up to 1,000 hp, a Long-style clutch has a pressure plate with three sets of lugs that reside snugly inside three metal windows of a robust steel stamping. Though installing the Long-style in later-model vehicles can require some detail planning, the task is not too arduous and all formulations of disc materials from organic to sintered iron are available. In higher horsepower applications where some clutch slippage is desirable to encourage a smoother launch, the sintered-iron Long-style system is preferable. In common with the billet clutch, the Long-style also facilitates adjustment, both static base pressure (360 to 2,200psi) and centrifugal.

Race vehicles delivering above 900 to 1,000 hp require a billet multi-disc arrangement. These contain two or three clutch discs and are significantly stronger. To accommodate billet-style racing clutches, deep bellhousings are required. Made by firms like Browell or Trick Titanium, the twin-disc billet racing clutch operates in a housing of 8.250 in minimum; the triple layout requires a minimum dimension of 8.625 in.

Single-disc and dual-disc arrangements cost around $460 to $540 and $1,500 respectively; Long-style $925, and billets go for $3,600 (twin-disc) and $4,000 (triple-disc).

Lastly, three conditions that demand careful consideration. First, don’t over-gear: Higher gear ratios (lower numerically) severely overload the system. For example, a 3.55:1 rear gear will introduce a significantly greater load on the clutch than a 4.10:1.

Second, tire selection: Drag radials have a tendency to hook the tires rather than spin them. As a result they, too, will impose a greater load on the clutch system.

Third, a note on power adders: Adding nitrous, a supercharger or a turbocharger also imposes an instant burden on the clutch system.

Accordingly, always select a clutch system that’s rated higher than your current power level or your anticipated level. Selecting a clutch system that is underrated ensures premature wear. Also, larger diameter clutches or clutches with more aggressive friction materials (a higher coefficient of friction) like metallic will address increased loads better, as does the dual-disc clutch.

Picking the right clutch is a balancing act between a number of variables to achieve the optimum combination of holding power, driveability, and durability. All told, operate your clutch properly under extreme loads in order to prevent drivetrain damage, pick the right type for your engine’s power, and also factor in your vehicle’s gearing, tires and power adders. Follow these tips and you’ll find your clutch holds much better under pressure.

Comments for: In the Clutch

comments powered by Disqus