Snap On's aerodynamically enhanced FFR Daytona Coupe

By Steve Temple

Photos courtesy of Factory Five Racing and John George

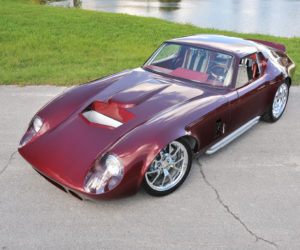

Beauty is more than skin deep — but let’s not overlook some obvious facial features. In a previous feature on Factory Five Racing’s coupe, we dug deep, focusing on a new chassis configuration that’s 14 times stiffer than the previous model. (See “Caged Coupe,” April 2017.) Now we’re more concerned about the skin — and not merely because it’s a beauty.

While the roofline emulates the Italian-crafted version of the original Cobra Daytona Coupe (with a sleeker, smoother shape than the American version), there’s way more to the aero treatment on this particular car, developed for Snap-on Tools as a promotional vehicle. (This particular coupe is the fourth such project done in concert with Snap-on, which has also sponsored FFR’s Cobra roadster, ’33 Ford street rod, and the 818 model.)

To find out more we spoke with both John George (whose white coupe served as the beta model for wind-tunnel testing), and FFR engineer Jim Schenck. The degree of effort and computer-aided design that went into streamlining this car, along with increasing downforce, was extraordinary. The NASCAR tunnel employed has load sensors at each wheel that precisely measure both lift and downforce, before imputing and analyzing the data in a CFD (computational fluid dynamics) software program. That’s a quantum leap in technology, when compared to the crude development techniques for the original Shelby coupe. (The airflow over that shape was determined in part by filming the car at speed with tufts of yarn taped to the body.)

Commenting on the improvements of FFR’s Gen-3 coupe, “We went over every square inch of this car,” Schenck says with a note of pride. “Every time we go to the wind tunnel, two or three things surprise us.”

Getting into the details, we’ll start at the nose. Right under the headlights, the Gen-2 body tucked in slightly, as did the original, but FFR’s John Crowel shaped a fascia, or nose cone, that eliminates this recess, which lowered drag and raised downforce.

“The front nose cone was the No. 1 improvement,” Schenck points out. He estimates that it reduced drag by as much as 14 percent. This number might not sound like much, but it’s hugely significant for a competition car.

Other design elements that keep the coupe stuck to the pavement are a pair of canards and a splitter attached to the front fascia. The headlight covers now have a cleaner shape for less drag. A diffuser was tested as well, but didn’t generate the desired results, so it was scrapped for the time being.

Along the sides of the body are large ducts, fittingly called wheel air exits, that release high pressure from within the wheel wells. Speaking of wheels, 18-inch Volk ZE-40 alloy rims were used in the build, weighing a feathery 20 pounds each, Schenck says.

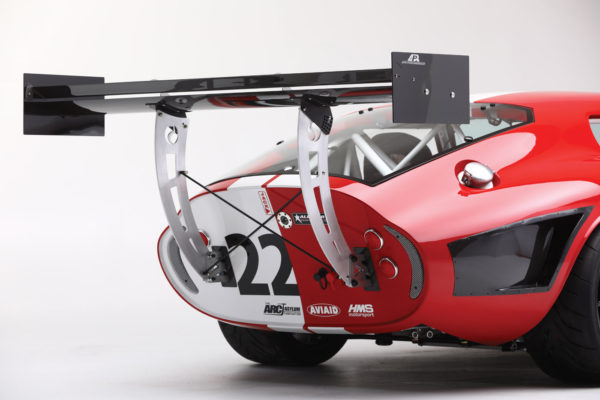

At the rear, you can’t miss that massive wing, an aftermarket piece made by APR. Schenck has wind-tunnel tested several wings over the years, and found this design to work best. The vertical supports are laser-cut aluminum, fabricated by FFR, bolted to the frame and X-braced with steel rods.

Look closely at the Kammback tail, and you’ll notice a pair of curved pieces just outboard of the taillights. These cover openings were initially intended to relieve air pressure, but actually sucked in air instead, so they were blocked off.

Some items on the body still create drag, such as the Le Mans gas cap and the Raydot side mirror. But not everything has to be precisely functional, as they’ve been retained to give the car a period-correct look.

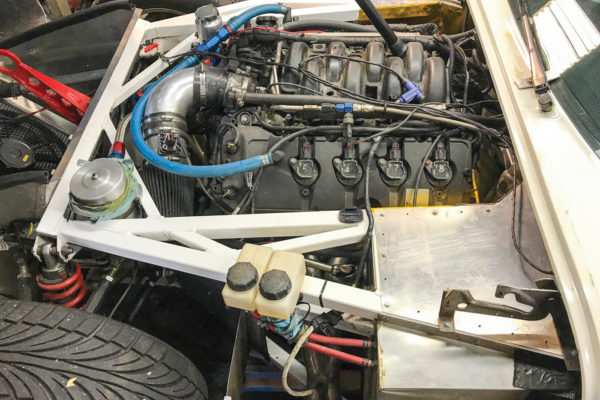

One aspect that’s clearly not traditional, though, is found under the hood: a Ford Performance 5.2-liter Aluminator XS, capable of producing more than 570 horses. It’s similar to the engine in the Mustang GT350, but differs in several ways. According to FPP (Ford Performance Parts) this aftermarket option combines all of the highest-performing Coyote engine parts built since 2011 into a single package. These include the Cobra Jet 5-liter 4V intake manifold, a 65 mm Cobra Jet billet aluminum throttle body, and fully CNC-ported 5.2 cylinder heads with custom high-lift camshafts, along with other internal upgrades.

This setup gives FFR’s Gen-3 way more power than the original 427-powered Super Coupe (but only slightly more than the engine in the latest big-block continuation coupe from Shelby American). Obviously with all these changes in engine output and aerodynamics, the chassis required some modifications, thanks in part to support from John George and his white coupe (see sidebar).

Perhaps one of the most telling incidents involved a test drive by NASCAR driver Joey Logano, manning the wheel of the red Snap-on coupe. After flogging it on the track, his comment? “Whatta cool car!” he enthused. “Can I take one home?”

Hey Joey — take a number. The line forms at the rear.

Testing the Beta Version

To get all the parts correct on the Snap-on coupe, FFR enlisted the aid of one its longtime customers and racers, John George. Previously he owned a Spec Racer, which he actively competed in for about 11 years in the ST2 class.

As he honed his skills, he hit the same wall that Carroll Shelby did — wind resistance. “It’s a giant brick,” John says of the roadster’s aerodynamics. Noting the 10 mph advantage of sleeker cars on the straightaway, “I needed a better shape.”

But just switching to a coupe configuration was not enough, so he worked closely with both Jim Schenck and Mark Dougherty of The Traveling Builder (who assists with FFR project cars) to optimize the aero treatment, adding one component at a time during a full day of wind-tunnel testing, along with on-track evaluations.

“The formula [for refining the car] was to relay verbally to Jim, the strategist, and Mark then wrenched on the car,” George says.

“What impressed me was how the chassis setup for my car was applied to the red coupe,” he notes. The spring rates, for instance, are much stiffer, as much as 200 pounds more per corner due to the effects of increased downforce. In addition, settings for the ride height, camber and caster were all derived from George’s coupe.

Other interesting details emerged along the way, such as setting the camber at negative 3 degrees, surprising since the Hoosier A7 tires have a much stiffer sidewall. But apparently the outside edges were heating up too much. Also, the ride height was lowered by a full inch compared with John’s roadster.

As for the aero mods, “We need both the front splitter and rear wing,” he points out. “You can’t just run one,” or the balance isn’t right. And the splitter was increased from 2 to 5 inches in size for more downforce.

All these changes have paid off on the road course, as John says he’s not fighting for grip, nor sawing at the wheel. And the numbers don’t lie: his white beta version of the red coupe, with basically all of the same aero mods but a lower hp engine, broke the elusive 2-minute barrier at Virginia International Raceway — a first for a Factory Five car! And it finished farther up the leader board than ever before, competing against a mix of the quickest amateurs and pro-level cars.

In addition, “The first two wins of the season came in June at NJMP, the second race weekend of the NASA NorthEast season,” John George notes. And he’s had other great races, besting Corvettes and Mazda RX7s in the ST2 class. Now he no longer trails them on the straightaways.

Comments for: Flying the Coupe

comments powered by Disqus