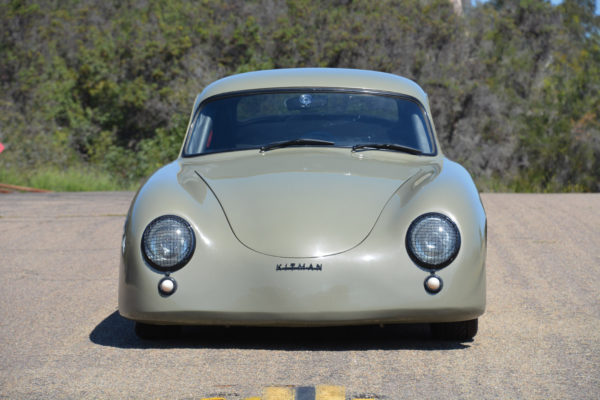

KitMan Motors 356 Coupe

Story and Photos by Larry Weiner

If it were easy, everybody would be doing it, right? That old saying certainly applies to developing a replica and bringing it to market. Just ask Chris Kleber, D.D.S. Although a dentist by profession, he’s always had a longing to cut his teeth on the replica car business. He opened wide and shared some of his teething pains in doing so.

“It all starts with a dream,” he notes. “We all have them as we read the car magazines or walk through car shows and museums. That special car that you feel defines you and your style or horsepower dreams.”

For Chris, it started with a neighbor’s white convertible Porsche 356A Speedster when he was in fifth grade. “It was so classy compared to our family’s blue 1962 Chevrolet Bel Air station wagon.” Later on while attending dental school, he could only afford a 1968 Volkswagen Beetle 1,300 cc, a “poor man’s Porsche” instead of the Speedster that he longed for.

Then he spotted an Intermeccanica Speedster replica that he realized was actually an affordable alternative, since scraping together enough money to buy a real 356 Porsche Speedster was out of the question. Already knowing how to work on VW Beetles, Chris figured this was the route to feeling the wind in his face, driving a homebuilt replica 356A Speedster down the winding California coastal highway. Just like James Dean would have done — except without the tragic accident.

Inspired by these two cars, Chris didn’t experience any collisions, but he did hit a few bumps in the road along the way in founding his own replica firm. After many years running a successful dental practice, he reasoned, how much harder could it be to run a replica firm? Ever done a root canal?

Chris came across the opportunity to invest in a company that manufactured replica 356 Speedsters, 356A Coupes and 550 Spyders. However, a series of unexpected business events ensued, presenting him with the chance to acquire the fiberglass molds of all of these models, along with chassis manufacturing equipment and marketing rights.

In developing a manufacturing facility, Chris concentrated on building cars to a “roller” stage, where individuals could finish their own cars to their specific personal tastes. His initial firm, operating under a different name, shipped these rollers overseas and to many areas of the United States. The internet kept expanding and this was — and still is — the main source of new customers. Taking roller cars to several car shows helped expand his market exposure. “We even had Austin Powers posing in one of the Speedsters!” (Fittingly, he was actually a look-alike of the Mike Myers character, a replica of Austin Powers if you will.)

Chris eventually parted ways with this precursor company, closing it down and establishing his own company, KitMan Motors, in April of 2016. With that change came even more challenges.

It was obvious to Chris that he needed to drill down deeper to improve the chassis, making it stronger and easier for the home or pro builder to complete. To make the chassis match and mount to the body, Chris worked with Ed Fenn of Fenn Chassis Research (who builds 200 mph salt flats racers) to develop a subframe that bolts directly to a shortened VW chassis. It permits both home and professional builders to attach the body directly to the chassis, rather than fiberglassing the body to the frame.

This custom, three-piece subframe weighs only 135 pounds and accepts either a coupe or Speedster body. It uses existing mounting points and is fitted on a modified VW pan, shortened from 94.5 inches to an 82.7-inch wheelbase. Modified and registered VW pans can be purchased with or without the subframe.

Another benefit of the subframe is that it can be used as a cutting template if the builder wants to shorten and recondition a 1967-71 VW Beetle chassis themselves, instead of purchasing one already done by KitMan Motors.

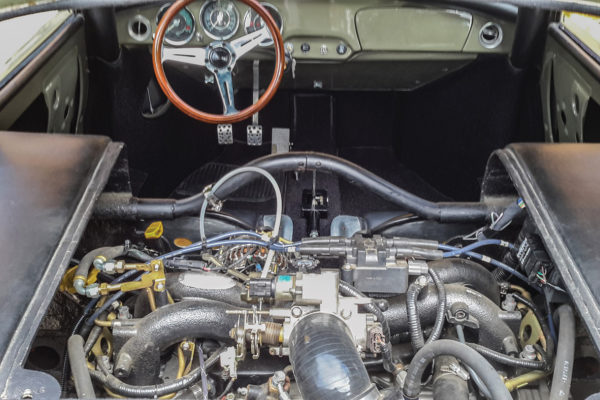

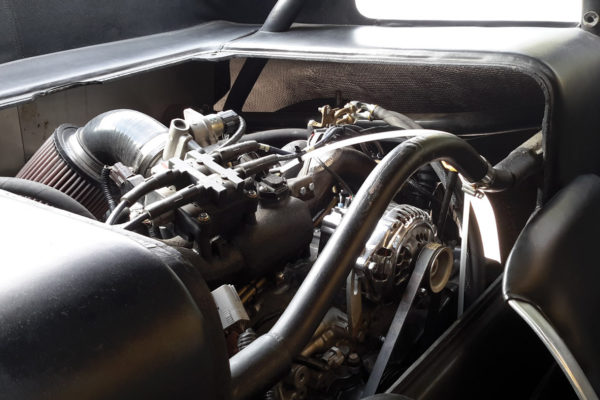

Alternatively, a custom tube frame is available as well, (also developed by Ed). It’s engineered to handle a higher-powered engine for those customers who relish a livelier level of performance, or even track duty. The floor is made of 16-gauge steel, and the total weight of the KitMan tube chassis is 280 pounds. It uses standard ball-joint beam axles up front and an enhanced VW IRS in the rear.

The pan of the tube chassis resembles a reinforced VW Beetle pan, but with a thicker gauge sheet metal. The tubular chassis uses a standard VW pedal assembly, with guide tubes for the clutch and accelerator cables built into the reinforced tunnel. An integrated VW rear torsion assembly with a factory VIN makes registering the car with the DMV easier.

Surprisingly, the coupe is the company’s most popular body style, even though it’s a more challenging car to build than the Speedster. The bodies are laid up in sunny Tijuana, Mexico, (ideal for curing the resin) and come in black gel coat. A hood, deck lid, dashboard, doors, and front and rear bumpers are included.

To strengthen areas of stress, such as on the rocker panels and doors hinge locations, a 1/4-inch-thick steel plate is embedded into the fiberglass. Total weight of the KitMan Coupe body is 350 pounds, and the full-up weight of a completed car is about 2,200 pounds (depending on the type of chassis used).

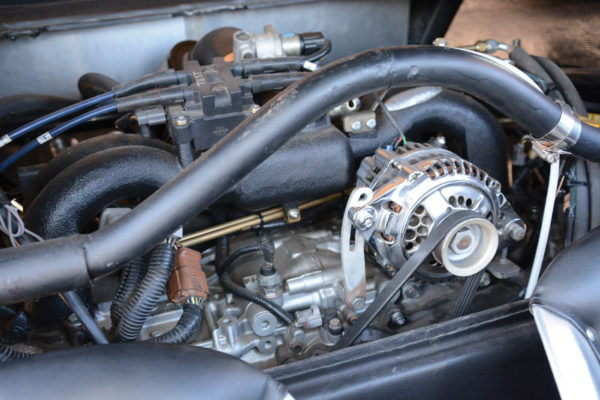

As part of his acquisition of the previous company that manufactured turnkey cars, Chris bought a half-finished 356A Coupe with a custom tube chassis and a midmounted 2.5-liter Subaru engine and many other custom features. He felt that finishing this special car would allow him to understand the build process better, and thus better assist prospective customers.

Chris points out that the car shown here has the identical coupe body that KitMan Motors now offers, and is nearly complete, with just a few finishing touches needed to be show ready. Even so, KitMan Motors is aptly named, as the company does not normally take cars to completion, but instead offers a component package that’s builder-friendly.

Chris isn’t content to rest on these projects, however. He’s now looking into creating a Spyder chassis, as he only offers a body at this time. But then again, Chris has never backed off from taking on fresh challenges, persevering with a big, healthy smile on his face.

Comments for: Wisdom Teeth

comments powered by Disqus