Repairing bodywork at home with prepreg fiberglass material

Story and Photos By Dan Burrill

Despite the versatility of fiberglass

for repairing car bodies and other components, it has a couple big drawbacks. The correct mixing and applying of resin and catalyst is potentially the most tiresome aspect. You have to get the ratio just right, depending on temperature and humidity. Also, brushing it on and rolling out the goopy excess resin is tedious and messy. There has to be a better way — and indeed there is.

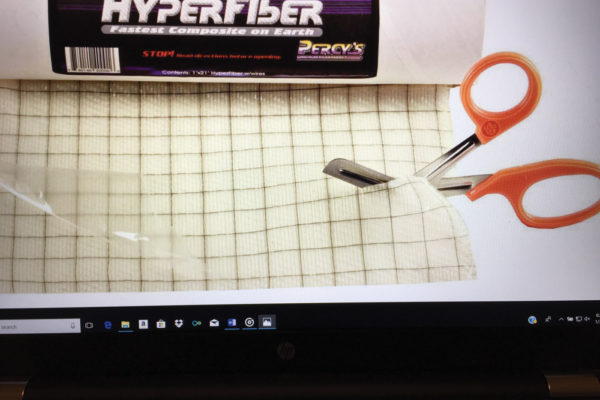

An alternative product on the composites market is called HyperFiber. This material greatly simplifies the layup process for a garage-based amateur. That’s because HyperFiber, a pre-impregnated fiberglass cloth sheet, cures to a solid in either UV light or direct sunlight. That’s possible because this product combines the fiber and resin, sandwiched between a dry plastic film on each side. The material already has the ideal ratio of cloth and resin and can be used for almost any small project.

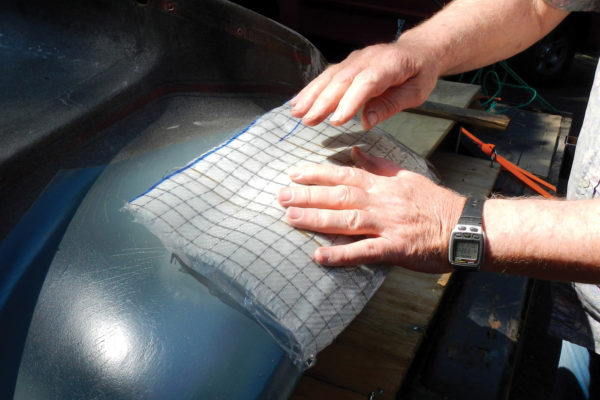

The DIY fabricator can use HyperFiber to make custom composite part in a matter of minutes, without mixing or applying anything. While this product does not bond to polyethylene or polypropylene, it can be used to repair or reinforce fiberglass, metal, wood, and many other composites and materials quickly, and without access to a workshop.

To illustrate, we started with a classic Kellison dune buggy body that had a big chunk missing out of the right rear fender. Follow along with the photos and captions to see how we used prepreg fiberglass material for a quick and easy repair.

Comments for: Patch Job

comments powered by Disqus