Fitting Z06 drivetrain and suspension into a C2 Corvette

Story and photos by Steve Temple

While using Corvette C4 parts to rejuvenate an older car is fairly common, C5 components are used less, since they present more challenges. How so? Just ask John Hadorn about his ’60 Corvette.

He came about his 1960 Corvette in a roundabout way, as it had been walled up in a garage for about 15 years, in order to prevent any damage from items being stored around it. After prying it out of its self-imposed prison, he intended to restore this classic to an original state with matching numbers. It already had a replaced 283 ci, but without a period-correct 519 block casting number. After working on the project part time for about four years, fixing the frame, chasing down a correct block and rebuilding the drivetrain, he took a hiatus.

The pause in his progress turned out to be a good thing, as he began to ponder over all the drawbacks of the original chassis. The C1’s foundation was a heavy, lumbering design, dating back to a 1949 Chevy sedan. That’s why a number of enterprising aftermarket companies have developed replacements for it, using a far more modern chassis setup.

SRIII is one such firm, which prompted Hadorn to swap out the underpinnings while still working on its restoration. But this change led to a host of other technical challenges along the way. It was about the time Chevrolet had released the Z06 Corvette, and he began to consider how he could integrate aspects of the new Z06 into an old body.

After traveling from Arizona to Illinois for a personal visit with SRIII’s Mike Stockdale, Hadorn checked out the design of the frame. It features round-tube construction, triangulated for increased strength and rigidity. The SRIII’s three-dimensional network of tubing is engineered to better resist the twisting forces applied during hard cornering and acceleration.

It’s also hundreds of pounds lighter than the antiquated chassis used on the solid-axle ’53 to ’62 Corvettes. When coupled with the 1984-and-later Corvette forged aluminum suspension (also much lighter than the original components), unsprung weight is reduced as well, providing a softer, more controlled ride.

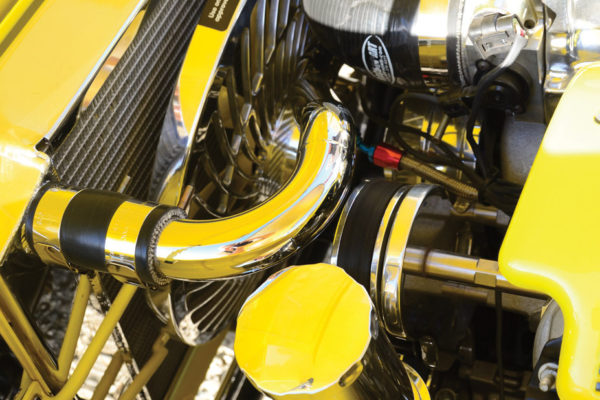

Typically, C5 components are used up front, and C4 out back. Why so? Stockdale points out that using a narrowed C5 up front provides a total 3 inches of additional clearance between the upper control-arm plates, compared to the stock C4 cradle. The extra 1.5 inches on each side of the engine provides additional clearance for the exhaust headers or manifolds, plus the steering linkage to the power rack. This spacing also simplifies the installation of a newer LS motor by not having to modify the heater hose pipes on the passenger side of the water pump.

Other advantages of the C5 include lower front sway bar mounts, again providing for more clearance. And the C5 front geometry is more refined and smoother than the C4. Even so, the front power rack and pinion is C4, since the C5 rack is otherwise too big to fit, Hadorn explains. Last but not least, the C5’s two-piston front brake calipers and 13-inch rotors are superior to the C4 big-brake option.

On the other hand, Stockdale notes, in ’97 the fifth-generation Corvette debuted with the rear-mounted transmission connected to the engine by an aluminum torque tube, which posed challenges to fitting it under earlier models of Corvettes. Installing a C4 independent rear end is simpler, since it locates the transmission up front with a standard driveshaft. And it also weighs less, making it the more logical option for updating the rear suspension of a C1, C2 or C3 Corvette.

Despite the difficulty of using a C5 rear end under a C1 Corvette, Hadorn was not one to be deterred. After inspecting an alternate C5 rear setup, he returned to Arizona and Stockdale began tracking down all the necessary drivetrain and suspension parts for him from a salvage yard in northern Illinois.

A few months later, Hadorn came across a new Corvette restoration shop, Speedway Customs, located in Lake Havasu City, Arizona. There he met the owners, Jay and Colleen Jorgensen.

“I was looking to get some minor glass work done on the body,” Hadorn recalls — but this job turned out to be more than minor. “We spoke about what I wanted done and Jay showed me a ’54 custom that he had just completed. That’s when the vision of the car began to take shape.”

To marry both old and new, Speedway reworked both the transmission tunnel and trunk floor, the former by creating a larger, boxed shape to increase the clearance. As for the floor, since QA-1 coilovers would be replacing the C5’s monoleaf spring, the trunk corners had to be cut out and re-glassed with inserts, using taller box-shaped pieces as well. To make more room for the SRIII frame, the spare tire area was flattened, and the rear of the body reshaped to fit a custom exhaust.

Other modifications included splitting and re-welding the rear-suspension cradle in order to narrow it to fit underneath the body. Other customizing consisted of reworking the bellhousing for the Tremec T56 M12 six-speed manual, and the Z06 rear end, which runs a 3.42:1 ratio and has shortened and re-splined axle shafts.

The C5 torque tube was too long, so it was cut and then sectioned with a reinforcing inner sleeve. Lastly, both front and rear sway bars were shortened and sectioned as well. All told, this choice of a C5 rear end was no simple deal, requiring a domino effect of changes to accommodate it.

Hadorn persevered, though. While the chassis and body mods were underway, he obtained an LS6 crate engine from a local Chevy dealer. While not required for fitting the new mill under the hood, he had the engine bay smoothed before dropping it in place. He bolted on a custom exhaust system with 2 1/2-inch tubing constructed of polished stainless steel with step headers and merge collectors, plus Borla mufflers and tips.

In the cockpit, the custom-painted center console area features a 1960 clock and defrost panel, but it was remolded for a Vintage Air system with oval vents/controls and electrical window controls. Other changes made to the cockpit area were removing the passenger-side grab bar and trimming 3 inches off the glove box between the seats (to make more room for the drivetrain). Wise Guys Seats provided new frames as well for accommodating the new drivetrain, which were upholstered by Nick Salas of Classy Auto Interiors.

Classic Instruments reworked a set of its SG Series gauges to fit the original housings. Phillips oval door handles, plus oval pedals for the brake and clutch, repeat this visual theme throughout the car. Finishing off the cockpit is a 15-inch Fast Line steering wheel from Billet Specialties, which also supplied the 18-inch rims, wrapped with Goodyear Eagle F1 rubber (245/40, front and rear). For sure stopping power, four of Baer’s Eradispeed two-piece rotors are clenched by Corvette C5 calipers.

All side and fender chrome pieces were removed for smoother lines, and to create a luminescent lemon hue, Speedway sprayed the body with Jamming Yellow pearl topcoat with SIKKENS auto clear III. Overall, the idea was to create a custom Corvette incorporating the performance of a newer Z06 while maintaining the essence of the original car.

Comments for: Squeeze Play

comments powered by Disqus