DX2 Rival exo car

Story and Photos by Jeff Zurschmeide

Track photos by Harold Klein

Building your own car isn’t for everyone — and even fewer are brave enough to start

with nothing more than a pile of steel tubing and a dream. But

that’s exactly what Del Loose of Salem, Oregon, did. He calls his car the DX2

Rival — because it rivals the look and performance of some other Miata-based customs. Why go to so much effort to build his dream from scratch?

“I like the idea of lightweight and fast,” Del notes. “But I didn’t just want to buy something. I said, you know what? I can build my own car.”

But not without a bit of help, as it takes a village to create a car. By day, Del is a field engineer for Rodgers Machinery, which manufactures industrial air equipment, and keeps him close to a wide variety of tools and experts in both welding and fabrication.

“We have some phenomenal welders, but I’ve never welded anything in the course of my work,” he admits. “So I asked the guys, and we practiced with the welders at work. Then I took the plunge and bought my own welder.”

Without a formal education in mechanical engineering, he relied on common sense to design a chassis that would withstand the stresses of a turbocharged sports car. Which required getting another piece of equipment.

“I bought a roller-bender and 2-inch dies,” he relates. “That’s how I bent the main roll hoop and the tubes on the side. Then I use the bender at work to make the rest of the bends.”

The Rival uses .095-wall, 2-inch-diameter DOM tube for the roll bar, and .083-wall 2-inch DOM on the main tubes. The body panels and floors are made of aluminum, for lightness.

“With a quarter-tank of gas, it weighs about 1,740 pounds, compared to about 2,100 pounds on a stock Miata,” Del points out.

Retail automakers spend millions of dollars to get the suspension geometry just right, and Del wanted to retain the predictable and high-performance handling of the donor Miata. So he built a jig to replicate the suspension geometry of the Miata in his custom chassis. The Rival also makes good use of both the front crossmember and rear subframe of the Miata, as well as the longitudinal power plant frame that connects the transmission to the rear structure. The overall design ties all parts of the car together, and thus allows the factory-built Miata components to soak up many of the stresses that would otherwise be carried into the space frame.

All told, “The weight distribution is 54 percent front and 46 percent rear with me in the car,” Del notes. “So it feels well balanced. The dampening is set middle of the road. It’s a little bit of a stiff ride at lower speeds, but that is in part because the chassis is stiffer than a Miata.”

By leveraging the basic engineering and geometry of the donor car, Del assured himself of a good-handling result right from the start. That put him months or years ahead in his project, and allowed him to focus on creating the look and the performance he wanted. The Mazda

Miata drivetrain is known to be rugged, and Del went through the donor engine completely before he put it

into his car.

“I bought a new set of stock pistons,” he shares, “and also forged rods, and had the head rebuilt. I assembled it myself.”

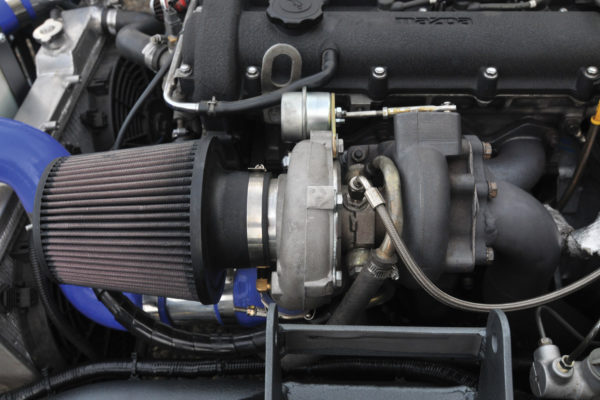

In stock form, the 1.6-liter Miata engine puts out about 116 hp and 100 lb-ft of torque. Del wanted quite a bit more than that, and tried several different-sized turbos before he found one that he liked, a Garrett 2860 unit.

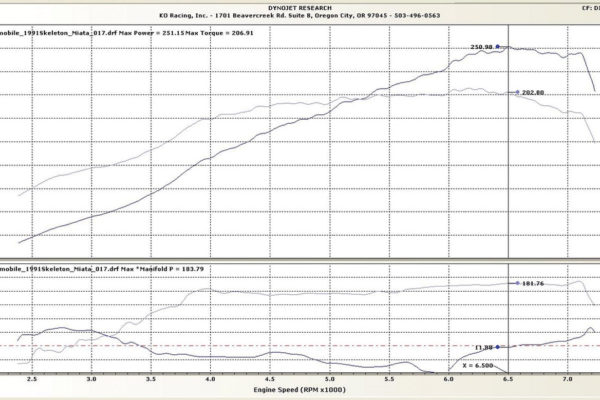

“I run about 14 pounds of boost,” he shares. “It seems to be working pretty good.” Indeed, as a dyno sheet indicates the Rival’s engine delivers an honest 251 hp and almost 207 lb-ft of torque to the rear wheels.

With that kind of power in a lightweight space frame, one of Del’s concerns is getting power to the ground effectively. The Rival’s transmission is the stock Mazda five-speed transmission, as is the independent rear axle assembly, while the differential itself is a Torsen limited-slip unit from a later year than the rest of the donor car. The Torsen unit debuted as an option on manual transmission Miatas in 1994, and is a vast improvement over the older viscous limited-slip diff, and even more so than the open diff on early Miatas.

With the 45-series tires on 15-inch wheels, Del has again chosen performance over a showy big-wheel look. The 225/45-15 Nitto competition tires offer the grip he needs to lay down the power, and less moment of inertia than larger wheels.

The brakes and steering gear, as well as the gauges and other ancillary components, are all sourced from the donor Miata. Del bent his own brake system hard lines, and invested in braided steel flex lines and a set of drilled and slotted rotors to complete the braking system.

With the hard stuff done, Del put a few finishing touches on the car, like the unique side-opening hood he designed.

“I like the hood because hardly any hoods open sideways,” Del notes. “It’s just kind of raw the way it’s open to the sides.”

Since completing the car, he’s participated in three different track events, a new experience for him. Yet he’s done quite well, with timed runs in the top 10, besting several dozen other cars in his second and third outings.

“I just really want to enjoy the car,” Del says. “It’s like driving a super-lightweight Miata with a lot more power. It corners better, accelerates, and stops on a dime, even with stock brakes. It has an extremely open feeling with the open sides and no top. It’s like driving a four-wheel superbike.”

Comments for: My Way Miata

comments powered by Disqus