Builder recalls the challenges with his Grand Sport kit

As Told by Larry Weiner

The Corvette Grand Sport kit from Mid-America was very well engineered. But like any project, I ran into challenges that had to be faced and overcome. The 1963 Chevrolet Corvette Grand Sport was a car that I dreamed about owning from the first time I saw photos of these amazing cars beating the Cobras at Nassau in the Bahamas.

Once I made the decision to build a Grand Sport, I drove from Chicago to meet with Jeff Leach at Mid America in Milan, Illinois to see the parts, chassis and a completed car in person. Jeff had a jig for building the tube chassis for the Grand Sport, and I saw the blueprints for the chassis, which even had General Motors markings on them, leaving a big impression on me.

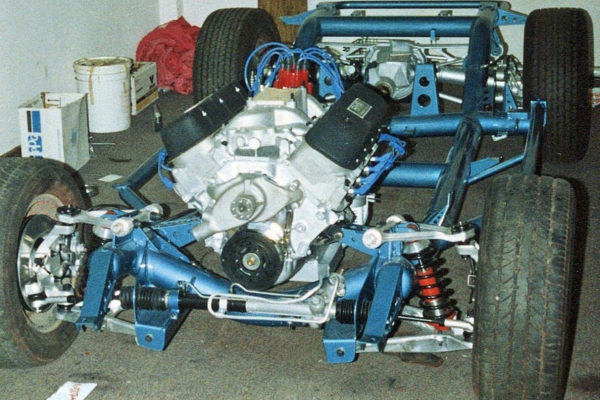

Once I was satisfied that this was a company I could work with, the first thing I did was purchase a tube chassis, the attendant hardware and a set of coilover shocks. Armed with these parts, I began my search to find an original mid-year Corvette body tub which is necessary to build the Grand Sport body.

This ended up being the first challenge, as I was determined not to cut up a complete car. I also wanted a tub with a title and VIN tag, which made it even harder to find. A couple of tubs I found had been cut up severely, and I was determined to find an excellent donor. It took two years of searching, but I finally found a 1965 coupe tub at Bloomington Gold in 1991. It was sitting on a chassis, had doors, and still had the factory tags and a Pennsylvania title. After a little negotiating, the seller and I came to terms, and I bought the tub, doors and title. The seller even delivered it to me after the show ended on Sunday.

Once I had the body tub, I called Jeff Leach at Mid America and made arrangements to deliver it to him to begin the process of building the complete body. Jeff had several jigs that he used to build the Grand Sport bodies that looked just like the jigs used at General Motors to build the actual cars back in the fall of 1962.

I contracted with Mid America to not only build the body, but also to paint it, and then do the body drop on the chassis after I had completed building it. The build of the body and paint ended up taking longer than originally planned, and once I delivered the rolling chassis to Mid America for the body drop, again it took longer than originally planned.

Once it was back home, there was still a lot of work to do. The car need to be wired, the interior needed to be created and dozens of other tasks needed tending to. Without a doubt, the biggest problem was the wiring. I am not an electrician, and I did not want to learn how on the Grand Sport. Fortunately, I had a good friend who is a professional electrician. He looked over the car and said that it would not be tough to wire since I only wanted the bare essentials, such as lights, gauges, and of course, the wiring for the engine. No radio, heat, air conditioning, or power windows.

I ordered up a set of Auto Meter gauges, an MSD 6AL box with a rev limiter and it was time to begin. He came over a couple of nights and got half the car wired, then because of personal problems, disappeared for a year! With the wiring half done, progress on the build of the car fell into never-never land.

I had several items custom made, among them I decided to have the aluminum plate for the instrument cluster engine turned. I found an older gentlemen in Arizona who did engine turning for vintage airplanes and sent it to him. It took months and numerous calls to get it back. Once done it was beautiful, but it bordered on being an act of Congress to get it done.

While I was trying to get my friend to come back and finish the wiring, I finished building the instrument cluster, installed the headlights and taillights, along with anything else I could do to keep forward movement on the project. Ultimately, it ground to a halt and at one point, I considered selling the car to a person who expressed interest in it.

However, one day the phone rang and it was my long-lost electrician friend. It seems he had not filed his income taxes for over three years and needed to get them in order so he could go to an accountant to get the filings done. I made him a deal. I would prepare all of his taxes for a professional preparer, and in exchange, he would finish wiring my Grand Sport. True to his word, he came over one night a week for several weeks and he finished wiring the car the same week I finished preparing his taxes.

He called me out to the garage and asked me to get into the car. Next he asked me to start the engine. It started on the first try, and I was so startled, I turned it off. He asked me what happened and I told him. His reply: “Ye of little faith!”

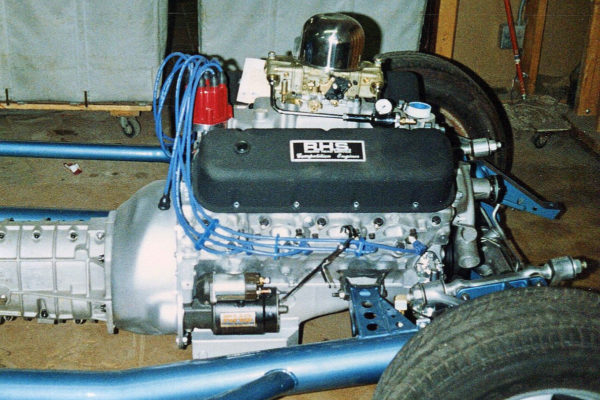

Another challenge was the intake manifold. When I had the 427 Chevrolet engine built by Racing Head Service, I specified a Weiand aluminum high-rise intake manifold. Unfortunately, it was too tall, even for the Daytona-style hood. The only thing to do was get a different intake. I ended up getting a 1970 Corvette LS5 low rise intake, which fit under the hood perfectly.

At the front of the manifold was a thermostat bypass that would connect to the top of the factory water pump. The aluminum water pump on my engine did not have this fitting, so I capped off the bypass with a rubber cap. One day, we displayed the Grand Sport at a car show. Warming up the engine, I cracked the throttle and blew the cap apart, covering the entire front of the car in antifreeze. What a mess. It took me the entire day to clean it all up. After the show, I purchased a stock style water pump with the bypass and solved that problem.

Yet another item that comes to mind was the fuel pump. I elected to use a Holley mechanical pump rather than an electric. Not long after we broke in the engine, I started having problems with the carb. It always ran rich and fouled the plugs. When I ran the fuel lines, I installed a fuel-pressure gauge in the line just head of the Holley 850 double pump carburetor and the fuel pressure was way too high. Next, I installed a fuel pressure regulator and dialed the pressure down to the correct amount. I next changed the carb and the problem was solved. Turns out that the fuel pump I had initially purchased was a street pump, but it was incorrect, and was a racing pump which required a regulator.

The headers also created a problem for the build. Not knowing better, I originally purchased a set of Hooker Side Headers for a 1963–1967 Corvette with a big block, only to find that these headers would not work with a tube chassis. They are designed for a stock chassis, which upon reflection, made total sense.

Fortunately, I found a person to purchase them and started over. I spoke to Jeff Leach at Mid America and as luck would have it, was in the process of jigging the first set of big block headers for the Grand Sport and would I like to purchase a production set. I said sure, and in fact, if it was possible, I would purchase the original jig set. No, those are going to the manufacturer who will be producing them. So I bought a production set from the initial order of three sets.

One evening I had brought the Grand Sport home after the body drop I decided to install the headers. After covering the tube chassis with towels and tape to protect the paint in case I the headers bumped it during the installation process, I went to work. To my dismay, they were not even close to fitting. One tube had to be completely redone with different bends, and several others had to be modified. Rather than send them back to Mid America, I worked with a local shop, who made the changes based on my markings and drawings. After several changes to the headers over a period of weeks, and installing them numerous times, they finally fit.

One final note: Having been cut apart, re-welded and massaged, the headers needed a protective coating. I learned years earlier that header paint will not stand the test of time. So I had the headers and side tubes Jet Hot Coated. This worked out perfectly and all the years I owned the car, the headers and tubes always looked like new.

Comments for: GRAND REALITIES

comments powered by Disqus