A Tour of the Scarab Skunkworks

Story and Photos by Dean Larson

Walking through the doors of Scarab Motorsports LLC was like a trip back in time in many ways. Steel tube chassis and aluminum body sections hung from the ceiling, and the shelves were stacked high with cast and fabricated metal parts. The shop floor had its fair share carts, jigs and various tools of the trade with just enough room to work in. While some of the shop’s projects were real throwbacks to bygone eras, a few hints of modern technology and engineering were evident in Scarab’s evolving development projects.

Richard Kitzmiller founded the Kansas City, Missouri, company Scarab Motorsports back in 2006 as a way to honor and revive the Scarab legacy. In a matter of years, Kitzmiller and his crew took an existing fiberglass-bodied Scarab recreation project, and fine-tuned it into a stunning aluminum-bodied continuation series. With small-block Chevrolet engines, knock-off wheels and iconic Scarab paintwork, the “street Scarab” roadster has the look and feel of the original with a few practical improvements under the skin; a Hilborn stack EFI system, and slightly modernized suspension and braking system are welcomed upgrades for street use.

After perfecting the street Scarab formula, the company announced an ambitious new project — a Meister Brauser Scarab worthy of FIA certification. This brought on several new challenges, including the fabrication and casting of extremely rare components from the original three Chevrolet-powered Scarabs. Recreating the Lehmann Engineering Cross Drive Unit for front engine accessories and the elaborate finned brake drums were just a couple of the crew’s hurdles to FIA approval. The finished Meister Brauser Scarab is a rolling testament to old-school fabrication and race car building methods.

Take a quick look around the Scarab Motorsports facility and you’ll get more than a healthy dose of vintage flavor. Obviously the beautiful ’50s race cars play a huge part, but we also thoroughly enjoyed the vintage tooling and equipment, including some machines that undoubtedly date back to the ’40s and ’50s. Shelving in the shop was piled high with aluminum seats, Scarab hoods, wheels, roll-bar hoops and those gnarly cast brake drums mentioned earlier. While Kitzmiller told us the crew would soon be moving to a larger facility, we relished in the old-school vibes of their current space.

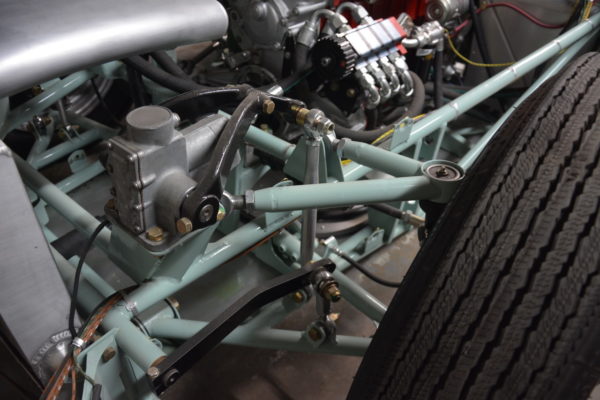

The raw Scarab up on the jig is destined to become a Meister Brauser car, evidenced by its authentic De Dion Tube rear axle currently under construction. The car’s frame jig was nothing high tech, a grid work laid out onto steel plate with square steel sections to clamp to, keeping everything square during assembly.

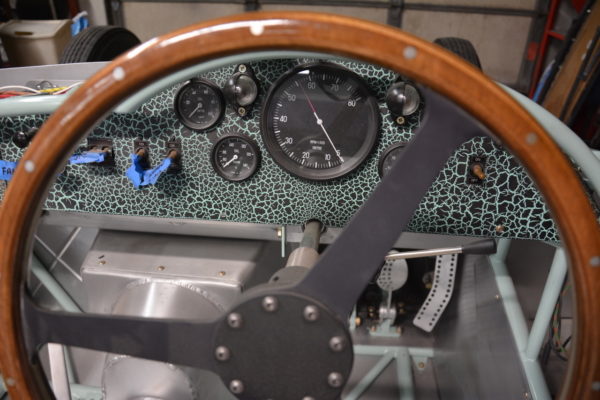

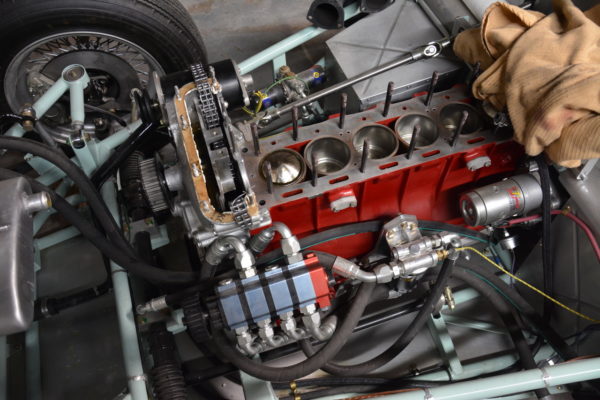

The stunning Aston Martin DBR1 nearing final assembly is an exacting replica of the model driven by Carroll Shelby. We poured over the details of the car for what seemed like hours. Its torsion-bar suspension, front hydraulic dampeners, De Dion Tube rear axle and WWII aircraft switches were a rolling history lesson in design. The paint effect used on the car’s dash was done in-house by one of the crewmembers, Beth Schmidt, and is accurate to the original. The hand built pedal assembly and elegant emergency brake handle also highlights the skills of Kitzmiller’s team.

But not everything at Scarab Motorsports harkens back to the past. While the company fabricates many of its own parts and panels, the larger body sections are fabricated overseas using a high-tech hydraulic process capable of forming large sections at a time. This method generates clean and repeatable parts and can be much quicker and cost effective than forming by hand. The development process for new chassis designs is also pretty tech-intensive, with many hours spent on CAD programs before a single piece of Chromoly or R8 steel is bent and TIG-welded.

The company is clearly well versed in old methods, but its newest development projects are impressive in their own right. Clamped into frame jig next to the Meister Scarab is another skunkworks project. It’s an LS3-powered open-wheel roadster that traces its roots back to the early ’50s. With aluminum bodywork, a six-speed TREMEC transmission and 495 horsepower on tap, this reincarnation of the 1953 Troy Roadster is bound to be a screamer. Be sure to check back next week for an exclusive rundown on this new continuation project.

Comments for: A Tour of the Scarab Skunkworks

comments powered by Disqus