Separating facts from fiction surrounding Weber Carburetors

By Jim Inglese

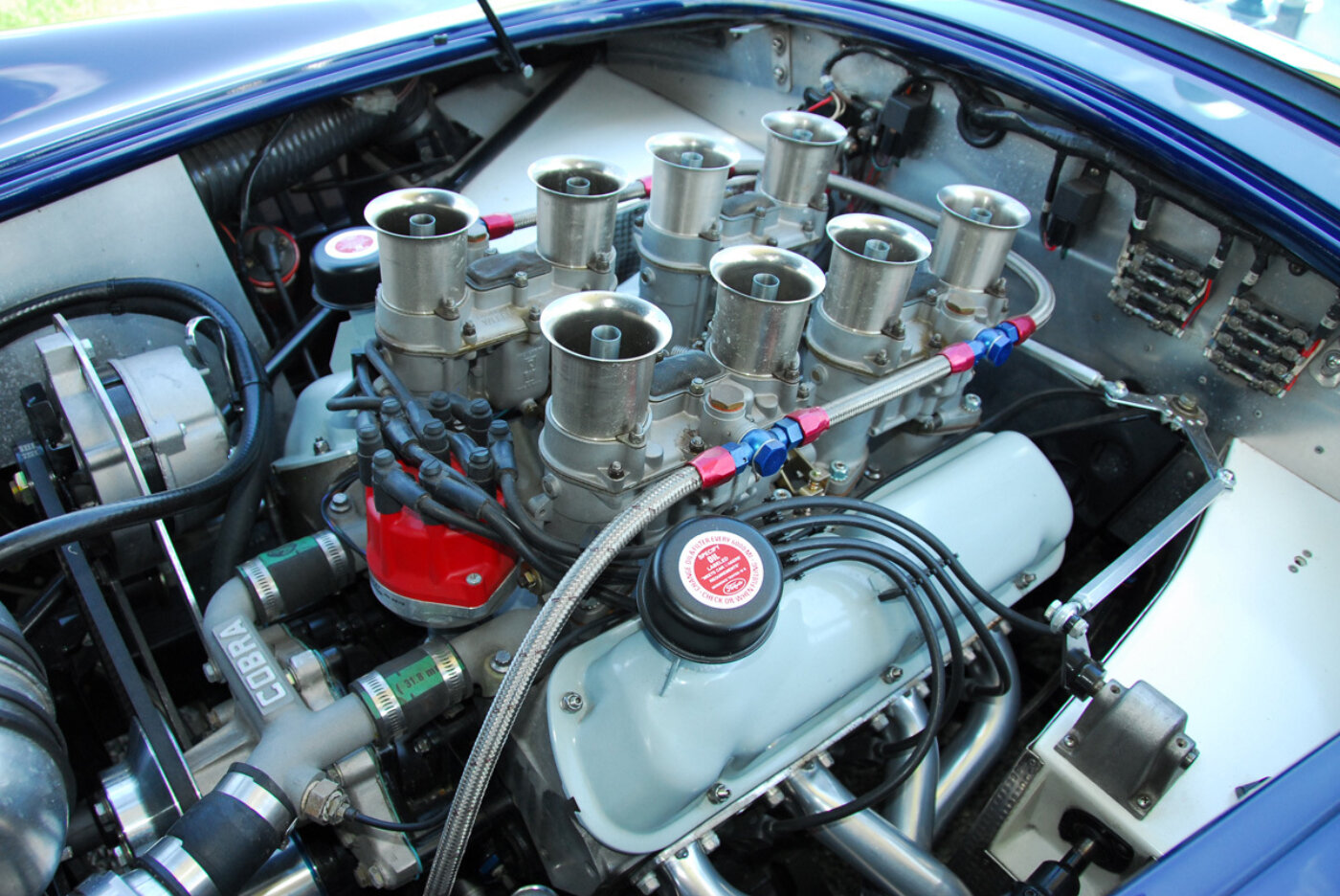

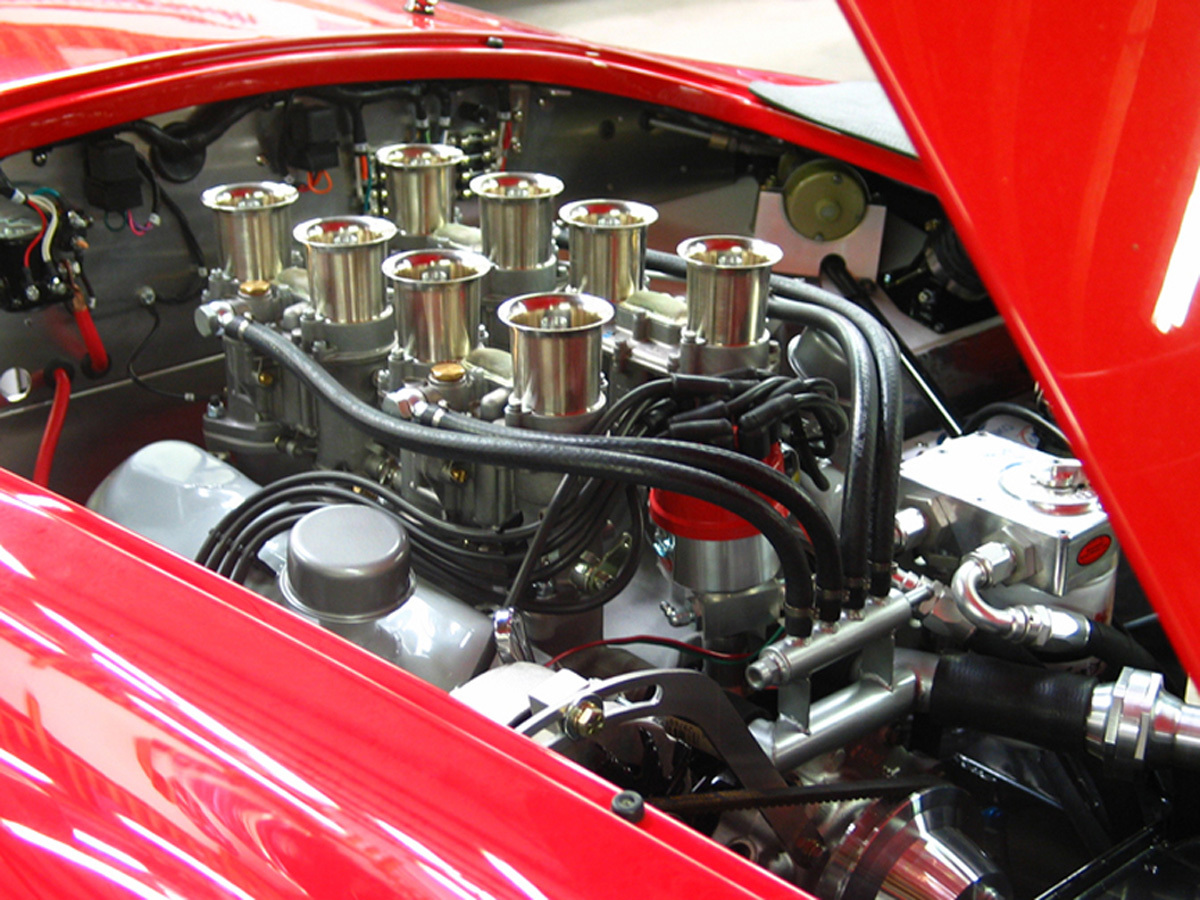

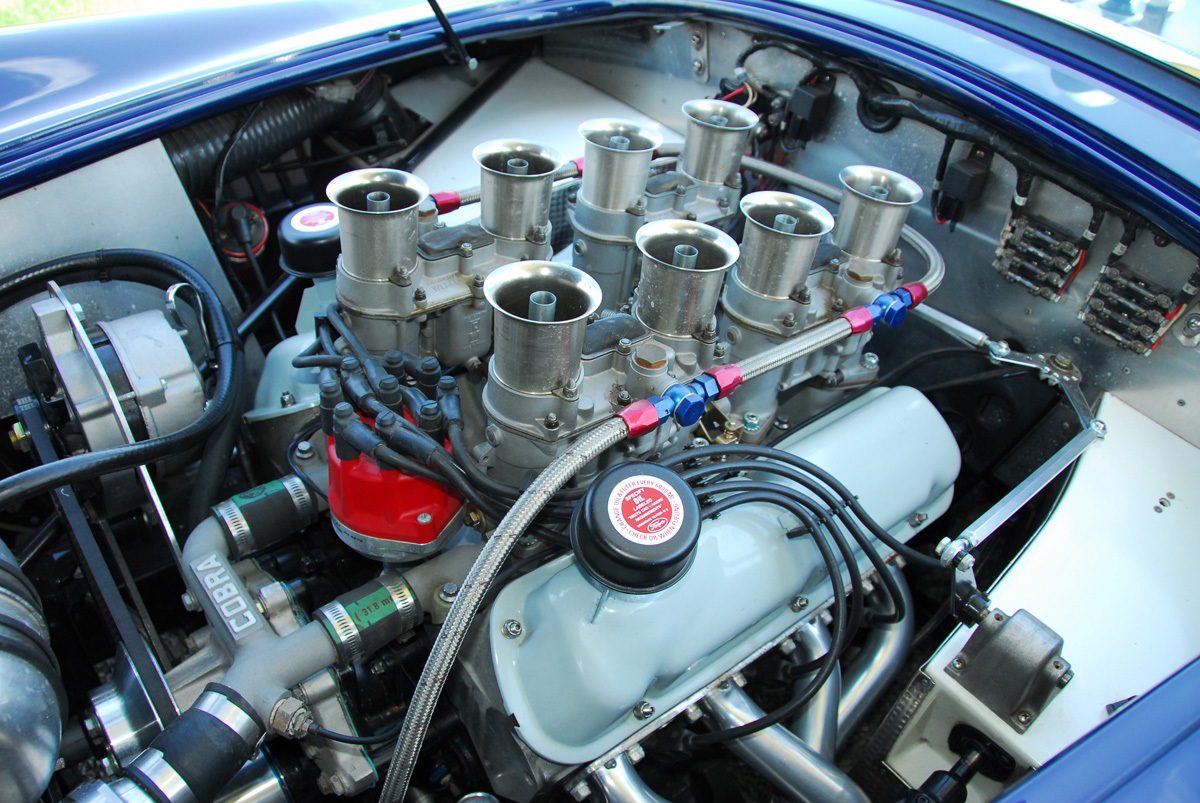

Today, just like back in the Sixties, any engine with Weber carburetors automatically commands attention. It’s really hard to walk by one without staring for a few seconds—maybe even a few minutes. Some 50 years after these enigmatic, visually fascinating carburetion systems saw their heyday, we still view them with respect and awe. That’s partly because they look just so downright impressive on a V8, with gaping stacks thrusting upward like eight hungry mouths.

Weber carbs are a true “bolt-on” package that, within hours, can visually transform any ho-hum utilitarian powerplant into an engine that looks like it belongs in a race car. And let’s face it, there’s a little bit of Walter Mitty in all of us—we like driving something that looks and runs like a race car.

The best part goes beyond the visual; driving a car with a Weber-carbureted V8 under the hood is pretty exciting. The instant throttle response, quick acceleration, and all that low and midrange torque become downright addictive.

There’s also a certain thrill that comes with knowing you’re running the same engine in your car that was the state-of-the-art in the Sixties. Feeling the same rush that legendary drivers felt when they stomped the throttle pedal to the floor makes the whole experience of owning one of these cars that much more visceral, and very real.

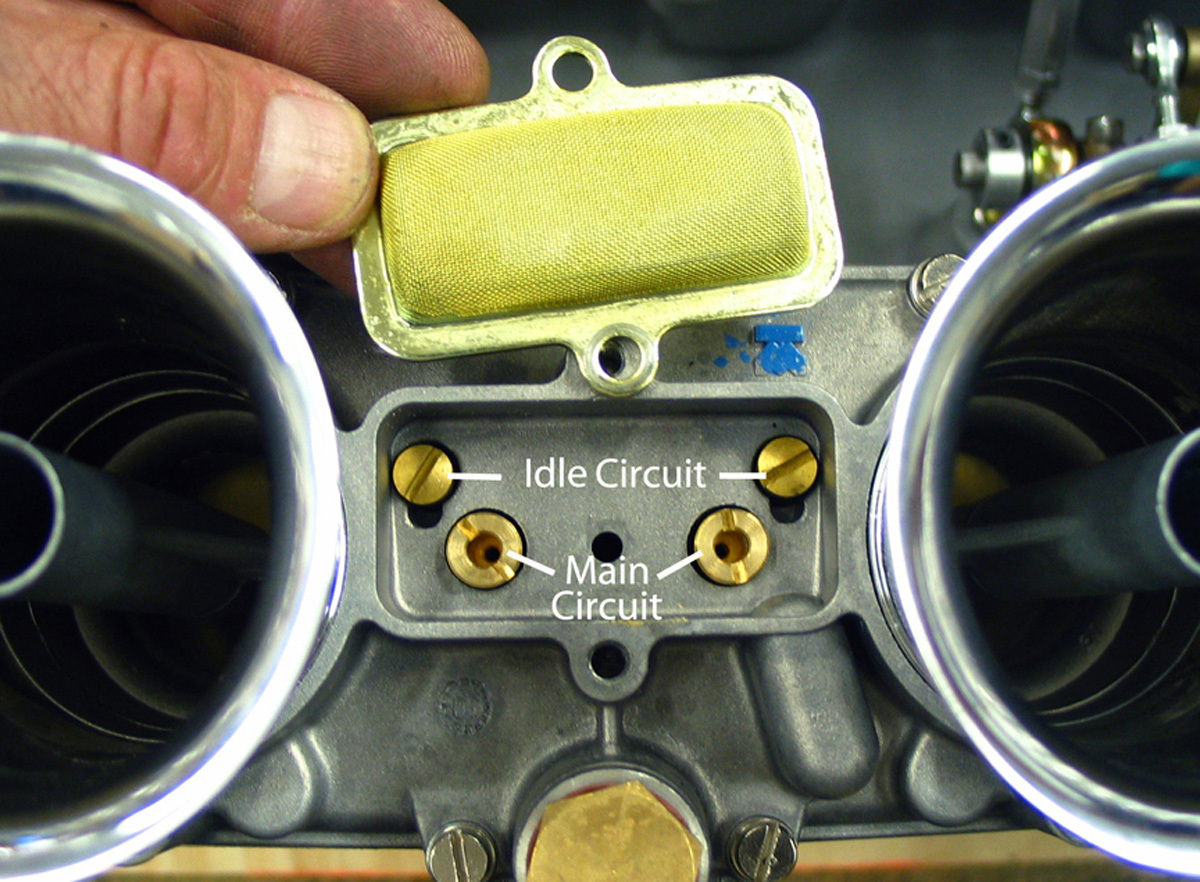

The interesting thing about Weber carburetors is how basic they are. They’re 100 percent mechanical, no software needed. You tune them with a screwdriver and a handful of jets. Down the road you go—done, nothing fancy, no laptop required. And changing jets is something anybody can do in a few minutes. All the jets are accessible from the outside, and you don’t need to take the carburetor apart.

So, what’s with all those stories we hear about Weber carburetors, all those things that “they” say. Such as, “Aren’t Webers really miserable to drive on the street?” And, “Won’t you be sorry for installing them?” Or, “If Webers are so great, then why are there so many bad stories out there if they aren’t true?”

Well, let’s separate fact from fiction. To start with, when Weber carburetors were the induction system found on every serious race car, the tuners and engine builders of the Sixties didn’t care much about how they worked under 2000 rpm, and they most certainly weren’t concerned about how the cars would drive on the way to the office every day, or how they behaved in traffic. Those race engines just had to make power, and that’s what they did.

One of the reasons Webers got a reputation for being difficult is simply that nobody really understood them back in the old days. They were racing carburetors. The engines were set-up on dynos and they made their power by finding the right combination of main jets and air correctors. When the horsepower numbers were acceptable, they dropped the engine into the car and they went racing.

Truthfully, Webers can be extremely unforgiving—but only when not set up properly in the low-speed circuit. They have to be jetted exactly right. Later on, a lot of guys who tried running Webers on the street suffered because of it, giving up and selling them in utter frustration. Things like fuel pressure, float levels, ignition timing, low-speed jetting, and emulsion tubes—it was all too much for the average guy who just didn’t have a complete understanding of how to work with these carburetors. And, there was really nobody to ask.

The Weber is a tuner’s carburetor. It can be made to do just about anything. But back then, nobody realized the float levels were not pre-set at the factory. To this very day, you can’t take a Weber carburetor out of the box and bolt it on. It doesn’t work that way.

The float level is just one small detail that could make the engine miserable even if everything else is right. And who knew that Weber carburetors are designed to run at a maximum of only 3.5 psi of fuel pressure? Weber doesn’t now, and never did, include an instruction sheet in the box. The company expected you to buy a factory manual. Nobody did, of course.

Meanwhile, race teams were running an aftermarket high-performance mechanical fuel pump, and sometimes they ran those big, pounding Stewart Warner 240A electric pumps, all of which were putting out well beyond 3.5 psi. Most fuel pumps typically put out anywhere between 9-12 psi of fuel pressure.

Unfortunately, the Weber needle and seat assembly, being designed for a lot less pressure, were lifting off their seats from excessive fuel pressure. So, lots of those Sixties-era race cars had carburetors that dripped at idle and they had to deal with the engines loading-up at low speeds—but after the race started, who cared? Once the engine was operating at the higher rpm’s, it cleared-out and pull hard.

In those days, sometimes a driver would shut the car off in the pits with the fuel lines over-pressurized and a hot engine compartment, so the carburetors would immediately start dripping. When the engine was fired up again, it would take some clearing out, and if there was a backfire through the carbs, there might even be a fire. Fuel pressure is very important, and that’s why there is such a thing as a fuel pressure regulator.

Those racing carburetion systems made their way through different hands and eventually, they were the ones that ended up on street cars. Now, picture the average Joe trying to drive that engine at low speeds on the street. It was worse than miserable. Pretty soon, he’d had enough. Time to sell those damn Weber carburetors and install a four-barrel.

Fast-forward to the present day. Weber carburetors might not be the induction of choice for a modern, high-tech, race engine. But remarkably, they are still the induction system of choice for any Sixties-era sports or race car that represented the “high-water mark” in racing and performance during the era, if you want authenticity. (Editor’s Note: Check out the Webers on some of the Cobras featured in this issue.)

Gaining any real level of an understanding of these carburetors and making them streetable really didn’t happen until the early Eighties. By that time, many of the Sixties-era race cars had been long sold-off, retired, or just pushed into the corner and covered-up. Around the late Seventies and early Eighties, a lot of these carburetion systems were available used, and they could be bought fairly cheaply at swap meets.

Understanding them, and getting them to drive on the street was entirely another matter, but they sure looked great. All it took was the time and patience of a few people who took a genuine interest in them at that time, and who saw a ready market for them in hot rods. Weber carburetion tuners were few and far between, but a few shops popped-up that actually specialized in them. Today, there are even some “old timers” left who have been doing it since then.

Make no mistake, Webers are a 100 percent tunable carburetor, so whatever the issue may be, there’s a solution to the problem. A carburetor is simply a device for the balance of fuel and air. You just have to understand the carburetor. Every circuit in a Weber carburetor can be addressed separately. Today, we know that the fuel level is oh-so-critical, so we pay a lot of attention to how the floats are set. And fuel pressure is the other huge factor. We know we have to run a special, low-pressure regulator, usually set at 2.5 psi.

Compression ratio is very important when the size of the carburetors is considered. Some engines need 44mm or 45mm carburetors, while other engines are more suited to 48mm carburetors. For instance, if you have a mild engine with 9.5:1 compression, forget about running 48’s. You need 44’s. If you run the 48’s, you’ll be complaining about soggy throttle response—but the 44’s will wake the engine right up.

As you would expect, one of the biggest complaints about Weber carburetors is that the engine may run badly at the lower speeds. There may be a lot of popping, blubbering, and possibly a flat spot. That’s a function of several factors, and the combination of jets and ignition timing are critical.

The thing about Webers is that they’re so unforgiving of not having the jetting package exactly right. With independent–runner manifolds, there’s no plenum to serve as a “central mixing and correction area.” Each cylinder has its own dedicated carburetor barrel, and the cylinders don’t get to borrow anything from their neighbors. The jetting and timing have to be exactly right.

The independent runner manifold makes for an extremely efficient engine; essentially, each cylinder is tuned individually. The idle jet, idle jet air bleed, emulsion tube type, and the ignition timing must all be in the right combination for any given engine’s specifications. It isn’t difficult to get all of it correct after a bit of road testing, if you are working with an experienced tuner, but for somebody just coming into it, trying to get it just right, starting from scratch, it can take a very long time to find the right combination for a given engine. It’s a lot like trying to re-invent the wheel.

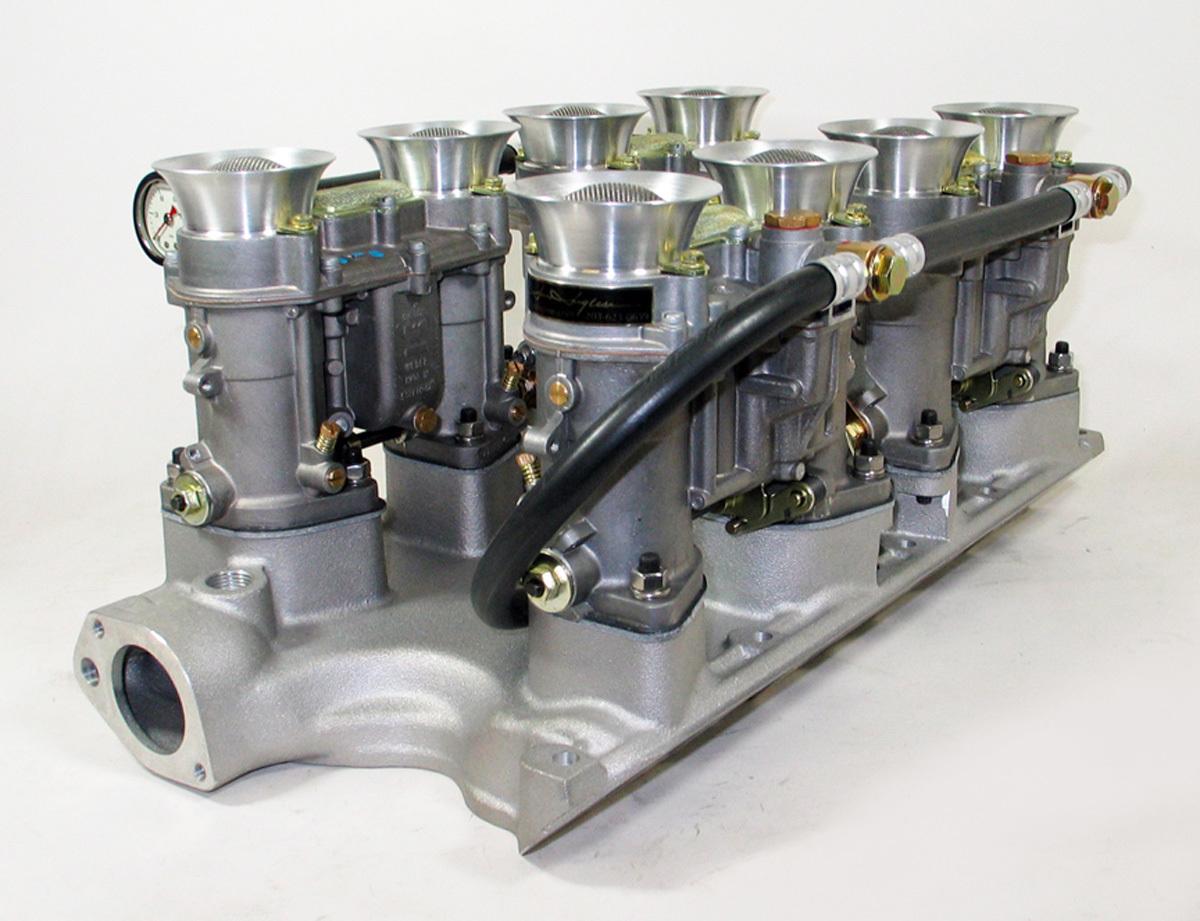

Today, it’s possible to supply your engine specs and other details, and just have a Weber carburetion system built for you that you can drive on the street and have some fun. If there’s a detailed tuning manual from a reputable builder who provides a lot of setup information, it becomes as close to foolproof as you can get.

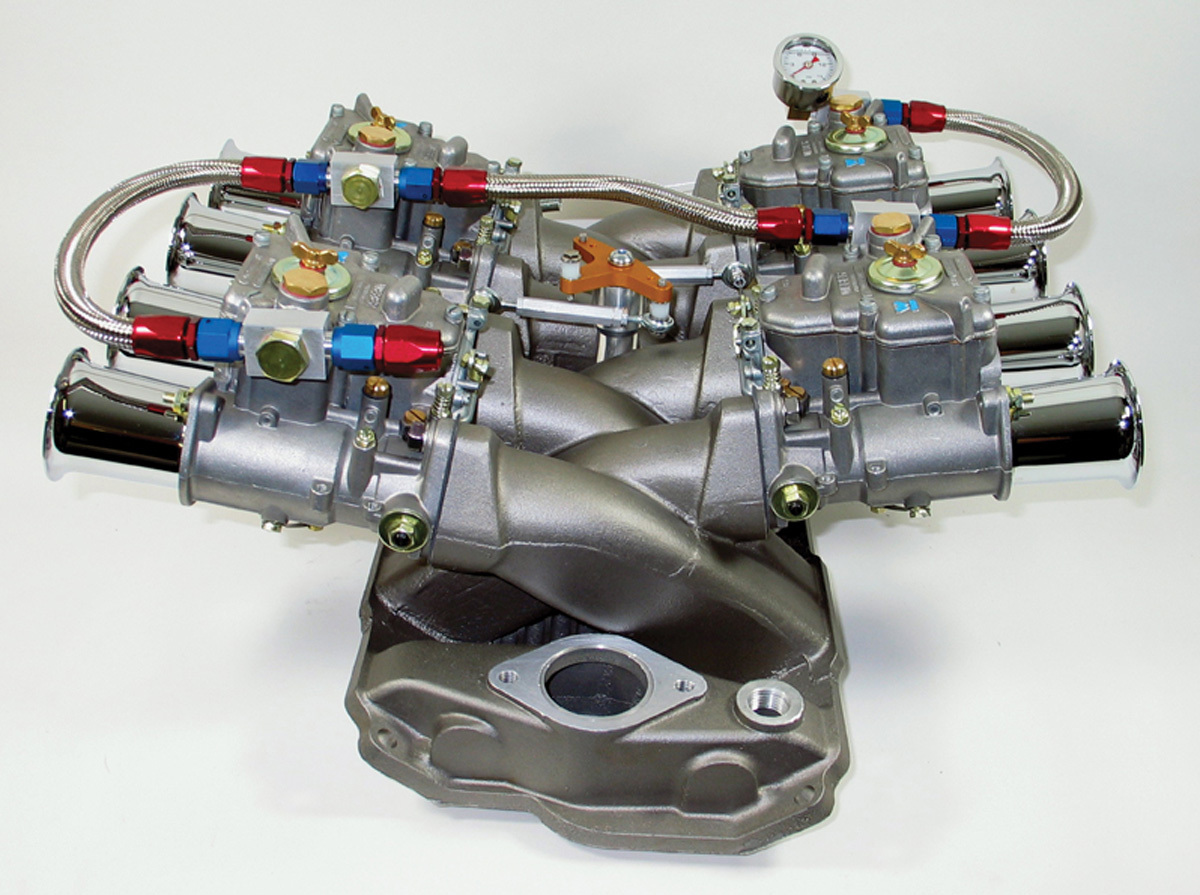

With Weber carburetion, 95 percent of the work is done on the bench. The installation is the easy part. A Weber carburetion system has to be built to match the engine it’s going on, and should be shipped to you pre-adjusted for a fast and easy startup. You should not have to add any parts, take the carburetors off the manifold to correct linkage issues, or figure out how to finish assembling the linkage. The mixture screws and idle speed settings should be pre-set for you to ensure the engine will fire-up quickly and idle for you.

If you have the ignition timing set properly, once you have fuel pressure, you should be able to pump the throttle twice, hit the key, and the engine should light-off instantly and idle for you. If you spend all afternoon trying to get the engine to run, you either set the timing wrong or you bought the carburetion unit from the wrong place.

Admittedly, it’s not easy to build a streetable Weber carburetion system from scratch if you don’t have a lot of experience doing it. The linkages are very tricky to assemble and can be confounding, and it’s easy to make a mistake that requires the entire unit to be disassembled in order to find the problem and make a correction. If any of the levers on the throttle shafts have just a few thousandths of play on the shafts, the unit will be impossible to keep synchronized and the engine will come off idle feeling rough, and it will idle rough as well.

So, if you’re thinking about Weber carburetion for your engine, the best advice is to do your homework. Get online and ask questions about the Weber carburetion suppliers in the forums. Talk to other guys who have bought them, ask where they got them, and most of all, ask how they were treated by their supplier if they called with any issues or questions following the sale.

Even a “cheap” Weber setup isn’t cheap, and will still cost thousands of dollars. Be sure to call and speak to the people who are going to assemble it for you, and be sure to make a list of questions, like how complete the unit is when you get it, whether it is custom-jetted for your engine, what work is done to the carburetors, what is not supplied, and what you’ll have to do or supply on your own.

Be sure to ask whether it arrives fully assembled and ready to drop onto your engine, all ready for startup. Most important, make sure there’s a complete set of detailed instructions to guide you through the installation, starting, and setup procedure—or you’ll be entirely on your own when you install it. If no instruction manual is supplied, will you be comfortable installing one of these systems and getting it set up all on your own?

The drivability of a properly tuned Weber-carbureted engine is no different than with a four barrel. The engine should idle smoothly and come up through the rpm range smoothly. Throttle response should be explosive. Anything less can be sorted out with some tuning.

Bottom line, when you drive a car with Weber-carburetors, there’s no reason why you shouldn’t be able to drive that car to work every day or to take it to the grocery store, ticking off every mile with a smile.

Comments for: WEBER CARBS

comments powered by Disqus