Removable Aluminum Paneling Factory Five Roadster

Text and Photos by John Lavet

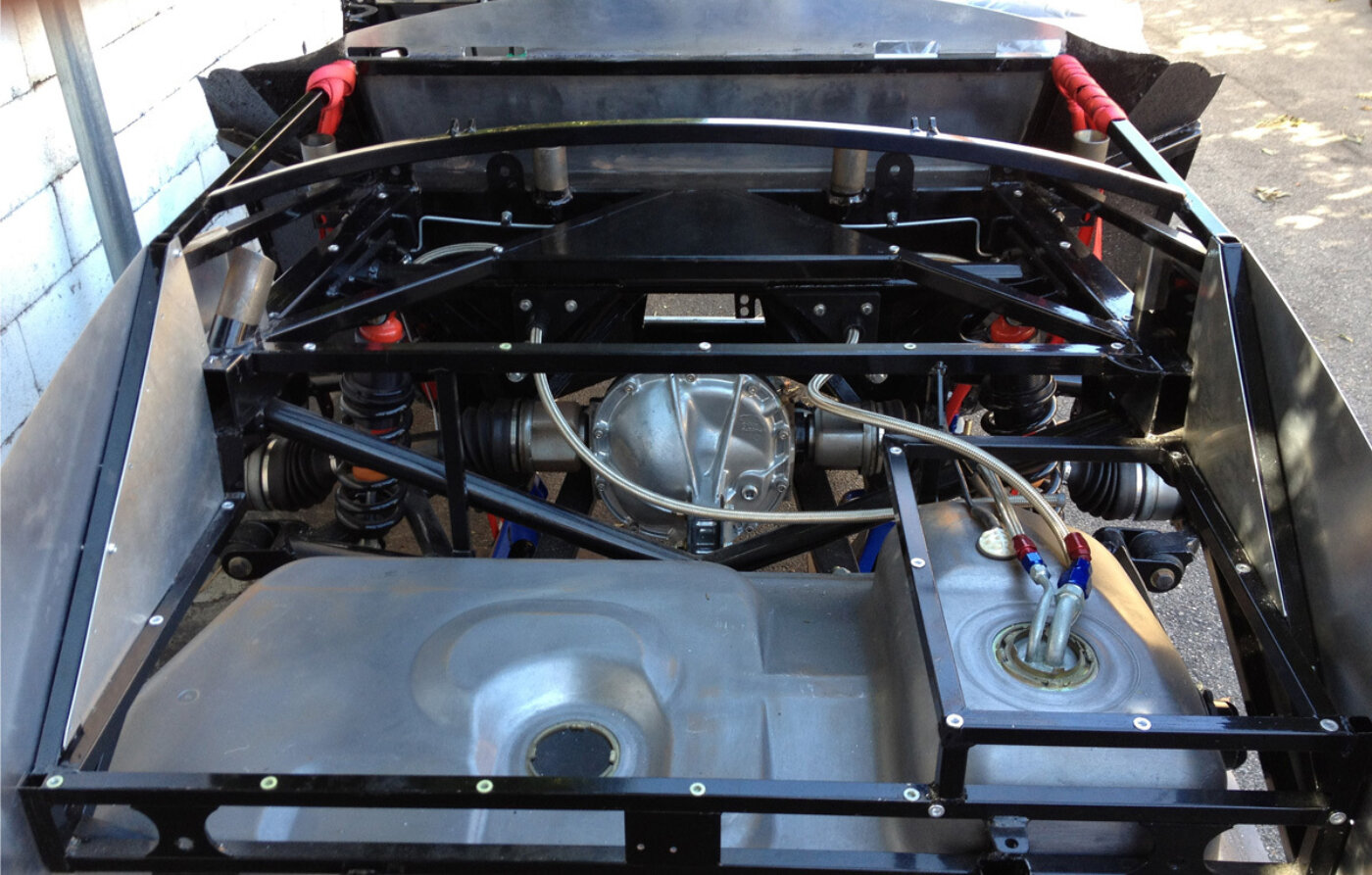

As soon as I started the buildup, I was impressed by the straightforwardness of the Factory Five Roadster. There is a certain simplicity and level of elbow room that’s really appealing. You can literally stand inside the engine compartment between the radiator and engine to make repairs. Also, since you are starting with the bare frame and adding components, you tend to make your own decisions regarding their placement and ease of access.

That design approach—and the fact that I don’t have the luxury of a hydraulic lift in my suburban garage—persuaded me to take the idea a bit further. I decided to make the aluminum trunk panels removable, along with adding a layer of rubber laminate on the frame surface in lieu of the usual, permanent silicone adhesive.

The advantage is that, when necessary, I’ll be able to conveniently get my hands (and tools) on the fuel tank ports, fuel and vapor lines, differential, rear suspension, etc. Of course, there still will be those times when I have to slide under the car, or when the suspension will need to be unweighted, or the beast will need to be put on a lift for some other reason. But the idea of making the maintenance/repair/modification process more efficient and hopefully less bone-jarring was a no-brainer.

hen doing so, here are a few tips: The 1/16-inch thickness of the rubber mat (available at most hardware stores) works out to be slightly thicker than the height of the flange on the top of the Rivnut. This extra smidgen provides a nice cushioning/dampening when the Allen bolts are tightened and the rubber is slightly compressed.

Also, to hold up to the considerable road and engine vibration, the Allen bolts need a locking agent, as there are no hex nuts holding them in place. Instead of a thread-locking compound, use, get this—clear nail polish. This non-gearhead solution was recommended by the industrial surplus guy who sold me the Rivnuts and Allen bolts. He uses it to lock the adjusting screws on his rifle scope, and swears that it holds up beautifully to the repeated percussion. He adds that the bond can easily be broken with torque from a screwdriver (or Allen head driver in my case). Then you can remove the aluminum panels for easier servicing or repair of the mechanicals underneath.

Comments for: RUBBER MATCH

comments powered by Disqus