Supercharging, 40 Percent More Output

By Bertie Scott Brown

Normal atmospheric pressure is easy and natural to breathe, since it’s only 14.7 psi. It’s the perfect arrangement for humans and animals alike, giving us all the respiration we need.

The same holds true for the engine in your car. In most cases, modern vehicles come from the assembly line with some form of a naturally aspirated power plant. This combination works just fine for the vast majority of drivers.

But that’s not us. Car builders thrive on exhilarating performance. After all, why build an anemic, lackluster ride?

One of the best approaches to gain more horsepower is supercharging. This form of forced induction has been around for over 130 years, and even helped generate the power for some of history’s greatest prop-driven fighter planes. This device is designed to grab Mother Nature by the scruff of the neck and shake her silly. Supercharging dramatically ups the ante on the pressure and quantity of the intake charge. As a consequence it generates significantly more power for the internal combustion engine. Let’s just call it “unnatural aspiration.”

Clearly, today’s technology brings power-adder designs to their highest levels of sophistication. Better still, they operate efficiently on stock and mildly tuned V8 applications.

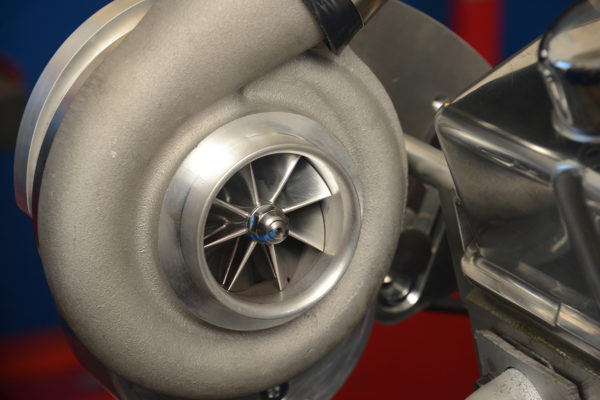

As one example, the aptly named TorqStorm currently offers blow-through, centrifugal superchargers for carbureted and throttle-body fuel injected applications that add 150 to 200 hp to these types of systems. The company’s latest rendition consists of complete and fully integrated packages with the potential of generating up to and beyond 700 horsepower.

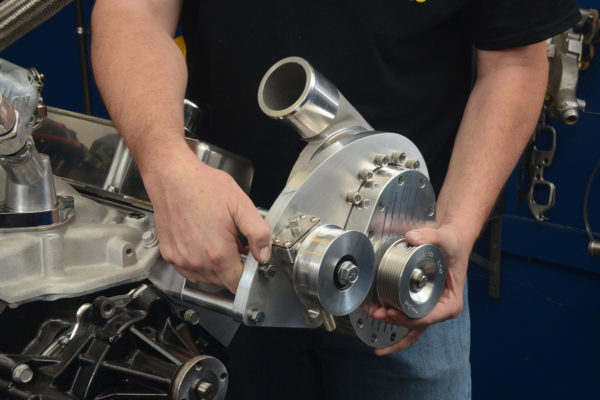

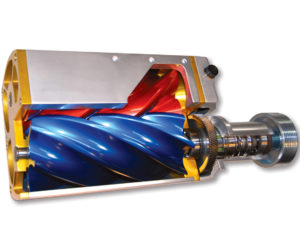

When a manufacturer incorporates the highest quality materials, supercharging becomes pretty darn close to rocket science. This one utilizes a machined 6061billet aluminum gear case housing that provides more rigid construction, thereby reducing bearing deflection and improving sealing characteristics at the same time. In addition, a self-contained oil supply system eliminates the plumbing hassle commonly associated with the installation of superchargers.

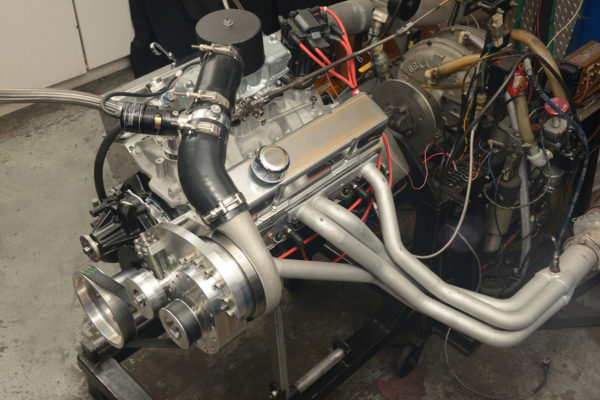

To establish a realistic level of performance for its product, this manufacturer teamed-up with three players in the market: First, BluePrint Engines acted as the source of the power plant itself, supplying a 383cid stroker small-block Chevrolet constructed specifically with forced induction in mind. Then Pace Performance conducted the installation of the complete supercharger system, while Atlanta-based powerhouse specialist Walden Automotive provided the facility for the dynamometer testing of this boosted engine.

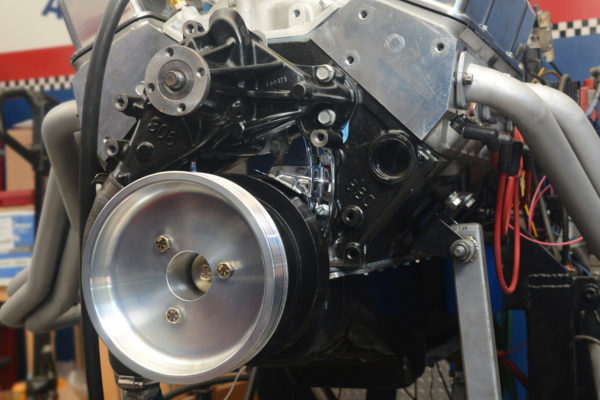

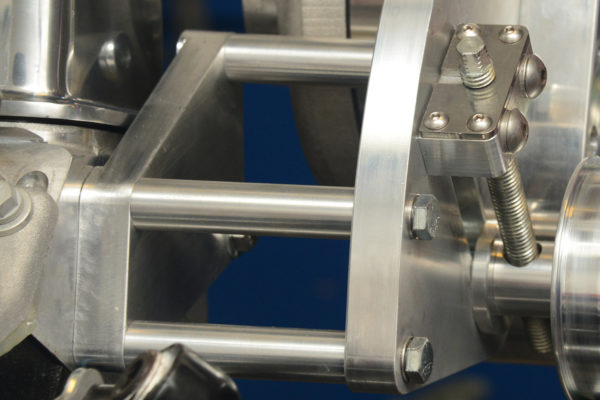

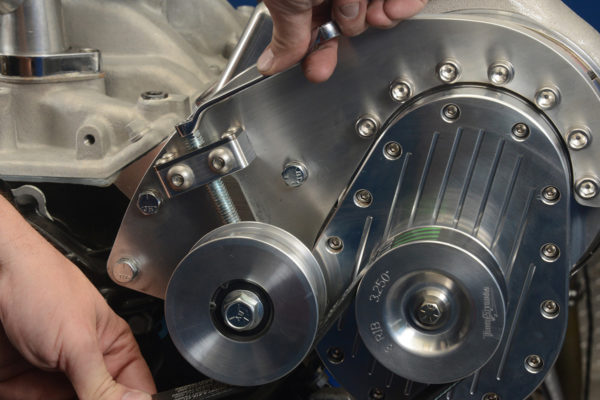

To ensure perfect alignment for the pulley-drive mechanism, the system’s mounting bracket is produced from 3/4-inch-thick machined billet aluminum. C-shaped, its objective is to eliminate any possibility of blower housing deflection. On this application, the bracket was mounted to the left cylinder head with three spacers and a backing plate.

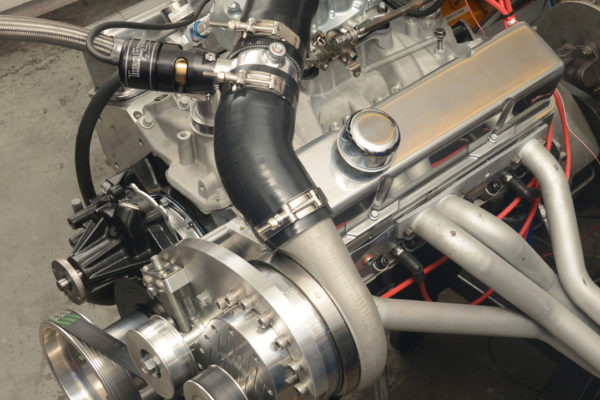

Next, the blower was secured to the sturdy bracket with seven socket-head bolts. To rotate the aluminum supercharger housing, sometimes known as the scroll, a sensible V-band clamping arrangement is provided, which eases alignment between the housing and the discharge hoses. The discharge hoses are routed to one of two options: a bonnet or an intercooler.

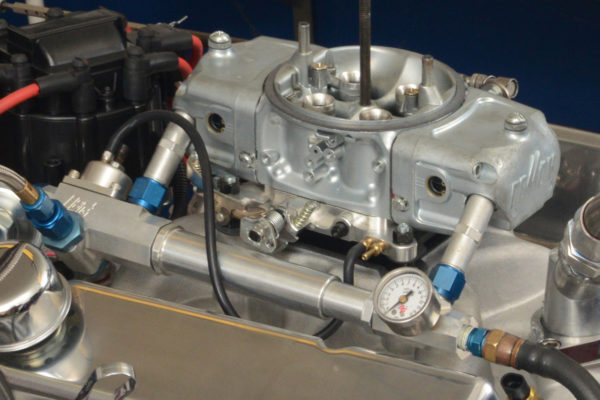

Obviously, supercharging increases the airflow rate substantially and, in this application, the responsibility for maintaining the correct air-fuel ratios is entrusted to a Demon blow-through 4-barrel carburetor.

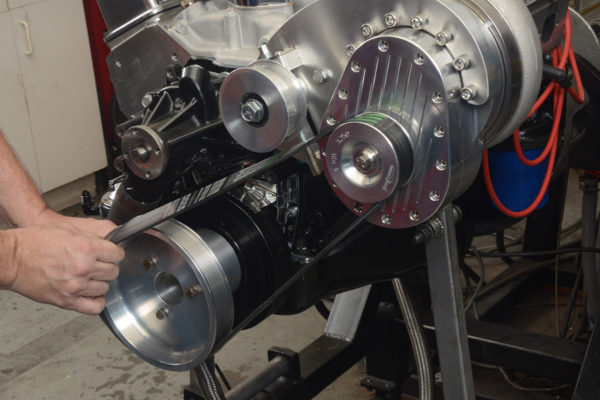

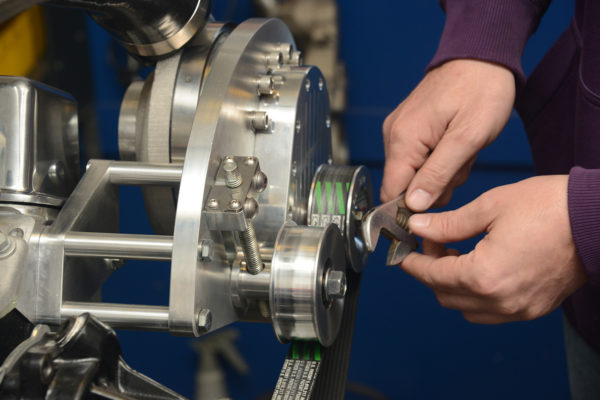

Once the carburetor is mounted on the intake manifold, it is connected to the two large-bore discharge tubes. Positioned between them is an in-line blow-off valve, which is secured with four stainless steel hose clamps. To complete the installation, a small-bore hose is connected to the boost pressure port of the carburetor by way of the blow-off valve. An 8-rib serpentine drive belt is installed then checked for proper seat and tension.

With regard to the numbers, in normally aspirated form, the 383 small block produced 440 hp and 472 lb/ft torque at 5,700 and 4,300 rpm respectively. With the supercharger system engaged, that same engine made 627 horses and 566 pounds of torque at 5,800 and 4,800 rpm respectively. To be precise, those number represent a 42.5 percent gain in horsepower!

In the dyno room, Rob Walden noted that the engine’s torque spread and throttle response wouldn’t likely be matched by any turbocharger. “Unlike exhaust-driven turbochargers where turbo lag is expected in the lower rpm ranges, this supercharger generated 400 lb/ft of torque at a leisurely 2,000 rpm. That’s as close to instantaneous horsepower as anyone could ask.”

All the better, the unit is lightweight and installation is not too complicated. It begins by attaching the crank pulley spacer to the engine’s harmonic damper. The following sequence of photos with illustrate how the TorqStorm centrifugal supercharger is supplied and then fitted on a small-block Chevrolet. It’s almost as easy as breathing!

Comments for: POWER ADDER

comments powered by Disqus