Mid-Engine Axle Tech

By Charlie Strickland, Strickland Racing

In a mid-engine car, whether a Lambo or GT40 replica, or any other exotic design, such as the Chupacabra, you can’t just pull drivetrain parts right off the shelf.

For instance, when you attempt to mate the popular Corvette C5 wheel hub to a Porsche/Audi transaxle or something similar, things can get complicated — and expensive. A set of custom-made CV axles runs about $1,500 to $2,000 per pair. On the other hand, there’s an acceptable hub solution readily available at the local parts store for under $100.

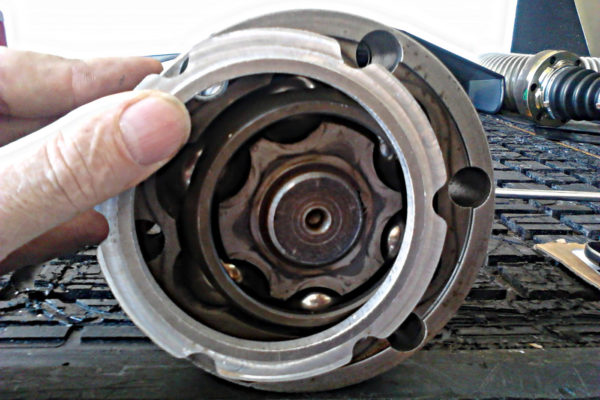

Before revealing this affordable alternative, and the somewhat involved procedure to find it, we should point out a few details. To start with, the C5 unit has 27 splines where the outer CV axle joint fits. Also, on the other end, there are six major styles of inner CV joints where the axle mates to the transaxle, all rather complicated except for the flange style. This simpler one looks exactly as described, with a flange on both the axle and transaxle that simply bolt together. The Porsche/Audi gearboxes popular for these cars all used a flange style to bolt up the inner CV joint, including the Porsche/Audi O1E, O16 and O1X boxes.

So what if a readily available CV axle could be found that has both a 27-spline outer joint for the C5 and a flange-style inner joint? It wouldn’t matter if the bolt patterns on the two flanges didn’t line up, since an adapter plate could be made much easier than custom axles.

In addition, some of the machining cost of the plate could be justified because one of them could then have the ring cut into it that sends the pulses to the Hall effect sensor for the speedometer. That ring is a necessary piece, and otherwise somewhat high-priced when purchased alone. Also, the plate thickness could be designed to accommodate and fine-tune the length of the available axles.

Armed with these various technical points, I set out for the local O’Reilly Auto Parts store and spent the whole afternoon with the A-1 Cardone Catalog, looking at every CV axle ever made. First I made a list of every axle with a 27-spline outer shaft, eliminating all that didn’t have a flange-style inner shaft. After further ignoring the lengths that were nowhere close to reasonable, about 20 axles remained and a pattern became clear — all were BMW large-sedan axles, plenty hefty, and under $100 each for new, not rebuilt, axles.

Unfortunately, while this setup ended costing about half that of custom axles, it required a custom-machined nut for a full engagement of the splines. How could it be improved upon? The newer C6 Corvette hub has 30 splines as opposed to 27. It costs about $20 more because it has an ABS sensor, but what axles would fit a 30-spline hub, and would they fit better? Could there be an even more efficient system that costs less?

Following another afternoon at O’Reilly’s for the same process of elimination, 12 axles of various acceptable lengths made the final cut. They are all Lexus sedan axles, cost under $100 new, and are again plenty hefty.

Because of the ring gear on one side of the transaxle, usually one axle is shorter than the other, which was true for the O1 series gearbox. Two axle lengths were selected to get the proper rear track width of my mid-engine design, the Chupacabra. Once they arrived, upon a test fit, the Chevy hub and the Lexus CV axle went together like they were made for each other. No more custom nut, and even though it ran $40 more for the Chevy hubs, it was $150 less for nuts.

Now for the next great surprise. When they were measured to get an idea of the adapter plate design, it turned out that the bolt pattern on the Lexus axle flange is the same bolt pattern for the Porsche/Audi gearbox flange! Chevy to Lexus to Porsche/Audi, who knew? Fortunately, there are enough length selections to hit the sweet spot (about 1 1/2 inches of play) on both sides without needing help from the adaptor plate.

Unlike earlier builds, the Chupacabra uses the new GPS sensor by VDO for the speedo. Besides the GPS unit sitting just beside the speedo (avoiding the hassle of running several difficult wires from the speedo back to the Hall effect sensor at the rear axle), there are economic advantages. The Hall effect ring is about $100, and the sensor is another $100, while the whole GPS system is about $100. Even with a free ring built into the adapter plate, the old-tech Hall effect is still the same price as the new GPS technology. So I’m not sorry to see the plate and ring disappear, and price-wise it is a wash with the new GPS, and less wires to run for a higher-end product.

The two possible downsides to eliminating the adapter plate didn’t materialize. Money, time and pieces have been removed from the build, which is always a good thing. I started with eight pieces at about $700, which were deemed adequate (and already superior to custom axles), and then replaced them with four excellent pieces totaling about $440. So now the entire axle assembly is truly “off the shelf.”

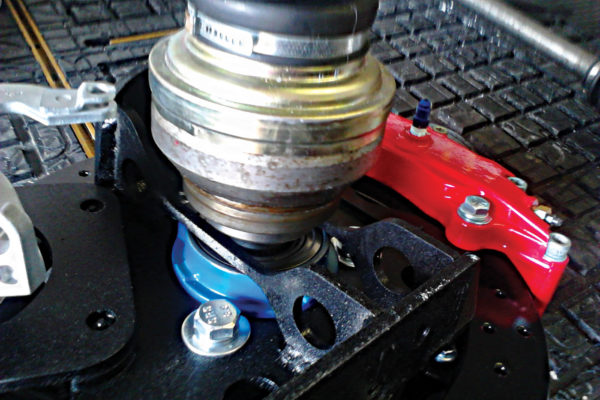

It doesn’t seem absolutely necessary, but a small “index ring” is CNC-cut in-house. It is made from leftover 1/4-inch aluminum plate used on the Chupacabra chassis. The six bolts holding the axle flange to the gearbox flange will index the axle adequately, but both pieces have slight circular indents, instead of one with the indent and the other with a shoulder that goes into it. This index ring goes between them and catches one indent on one side and one on the other, making a more positive index. It also provides a much better gasket seal surface on both sides, while the old adapter plates had to use a more difficult O-ring to ensure that the seal kept the axle grease inside.

Economy, durability, availability and simplicity — what’s not to like?

Comments for: Exotic Axles

comments powered by Disqus