United Pacific's ’32 Ford and Bronco

Story and Photos by Steve Temple

Although only 52,000 or so ’32 Ford five-window coupes were ever built, many more reproductions of the Deuce are on the road today. Looking at the economics of this phenomenon, it’s easy to understand why. But not all are created equal.

Clearly fiberglass bodies make for much easier and less expensive re-creations of the original, allowing for all sorts of modifications — and much higher production numbers, as noted. Much harder, though, is a precise replica of the steel-bodied original. United Pacific Industries certainly knows this fact firsthand.

Known for its massive assortment of reproduction hardware for 1928 to 1948 car models, the company spent more than five years of research and development work to reintroduce a truly authentic ’32 Standard Coupe body. It represents a logical extension of the United Pacific’s core business, as we’ll see. First, though, the man and events that led to this project.

The intriguing personality behind the operation is Major Lin, a Taiwanese-born engineer. After relocating to the U.S. in the late 1970s, he founded the company by manufacturing accessory parts for the heavy-duty trucking industry, an operation that still thrives by carrying more than 20,000 items in its Long Beach, California, distribution center.

That’s where we came across the company’s new ’32 Ford, which seemed a bit out of place in a massive warehouse operation, definitely a far cry from your typical mom and pop street rod shop. So how did Major transition into the reproduction market?

By the early 1980s, he realized an opportunity in the aftermarket parts industry for antique cars and began offering Model A hubcaps, splash aprons, radiator shells, door latches, taillights and so on. Major’s antique Ford product line continued to expand, to the point that a complete ’32 coupe A United Pacific Steel Bodies To get a clear view of just how clean United Pacific’s steel is, check out these shots of it in bare metal. This particular car is powered by the venerable flathead V8. body became feasible by digitally scanning a number of original 1932 Fords.

Using 3D design software ensured not only correct dimensional accuracy, but also close fitment of the body pieces. Once the forms were finalized on the computer, a CNC mill cut out a set of male and female dies that would serve as the tooling for stamping out parts in cold-rolled steel.

One slight change from the original was the use of 18-gauge sheet metal, rather than the slightly thinner 19-gauge that Henry Ford employed (likely to save money on production). Other pieces in the body use thicker, 14- to 16-gauge metal. All told, United Pacific either duplicated or upsized the thickness of the materials found throughout the original.

Another change United Pacific made is in the roof, which is a solid piece. Back in the day, Ford saved money by not stamping out a solid roof piece, and the top was a wood-framed open area with a cloth top. United Pacific also offers an open-top option, however, if so desired.

All these parts are actually made in Taiwan, which admittedly might raise some eyebrows among American street rod enthusiasts regarding their homegrown cars. So United Pacific went to great lengths to have prominent U.S. hot rod builders and restorers evaluate the quality of the panels. As proof of the pudding, one of these early bodies was built into a street rod by Roy Brizio for Vic Edelbrock Jr. In addition, the United Pacific ’32 coupe body is licensed by Ford Motor Co., an entirely voluntary arrangement by United Pacific, in order to achieve a mark of authenticity by the original manufacturer.

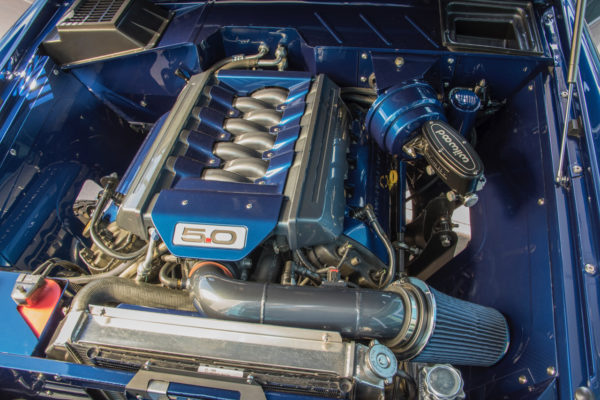

The particular car seen here, which is Major’s personal ride, has a highboy style overseen by Brizio. Bill Ganhal’s South City Rod and Custom chopped the top a moderate 2 inches. The body sits on a traditional frame welded up by Walden Speed Shop. It’s fitted with a Super Bell I-beam 4-inch drop axle and a Currie Enterprises 9-inch rear, all secured with Pete & Jakes Hot Rod Parts hardware and buggy springs. To top it all off, the Edelbrock/Ford 347 ci stroker V8 delivers way more grunt than the ’32 Ford’s original flattie.

How much more does a steel-bodied replica of a ’32 Ford run? You’re looking at $21K, significantly more than a typical fiberglass version that would include a chassis as well. But that’s the price you pay for the steely authenticity of a car that’s nearly indistinguishable from the original.

Bronco Reproduction

With older Ford Broncos rapidly escalating in value (and rot ting away as well), steel replacement panels are clearly in demand. As proof, take a look at United Pacific’s Bronco reproduction crafted by Maxlider Brothers Customs. Having built more than 500 classic Broncos, Maxlider’s top-of-the-line builds can start at $225,000 and cost as much as $500,000, depending on specifications.

United’s ’66- to ’77-style Bronco panels consist of everything necessary for completing a body. They include the fender flares, door shells, windshield and window frames, front and rear bumpers, door jambs, taillight housing panels, rocker panels and more. United Pacific also supplied the billet aluminum taillight bezels and LED sequential taillights for the build. In total, more than 60 products from United Pacific are used on the vehicle.

Granted, that doesn’t include the frame and suspension and you’ll have to handle the assembly and paintwork, but you’re way ahead of trying to restore and reweld a rusty original.

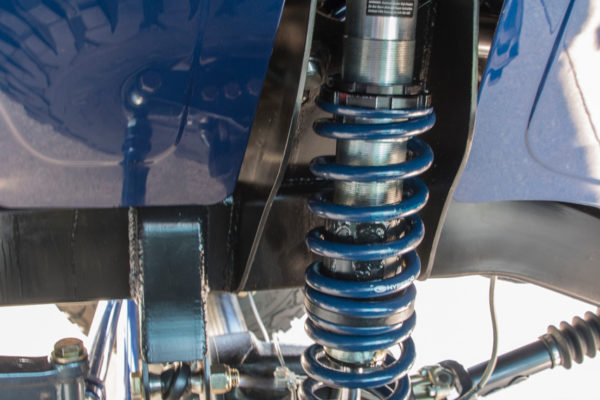

Maxlider fabricated a custom chassis fitted with a four-link front, three-link rear and long arms by Black Beard Broncos with Fox coilover shocks. Other chassis components consist of Currie Enterprises axle housings and Yukon Gear & Axle differentials and axles. Wilwood four-wheel discs also provide much improved stopping power and fade resistance over the original’s drum brakes

Leather upholstery dresses up the cockpit, along with a Classic Instruments gauge cluster and a Flaming River steering column. Wild Horses 4x4 supplied an array of trim items, plus a body lift as well.

Who would’ve thought the crude original Bronco could ever be transformed into such a show pony?

Comments for: Steely Authenticity

comments powered by Disqus