1955 Porsche 550 Spyder

Joe Schneider came to me with an idea of what he wanted. With my company only being in business for about a year and half at the time, I hadn't really been able to reveal what I was capable of as a builder yet. So I kept coming up with custom touches while building Joe’s Spyder, ideas that I’d run by him and he liked. It was a tough balance between trying to make his look original, yet using some outlaw touches.

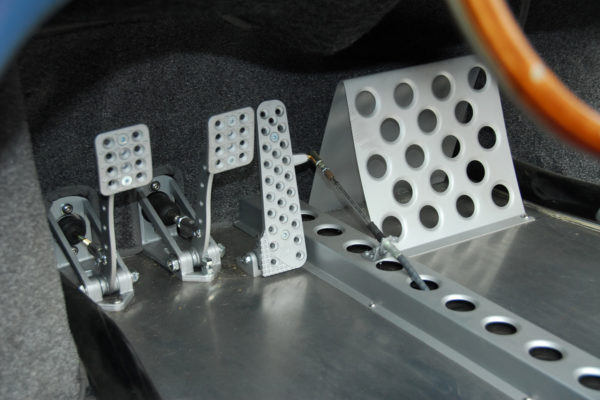

For instance, I drilled lightening holes in his door handles because he had seen it on an Outlaw that Magnus Walker was building at the same time. From there, Joe wanted lightening holes throughout his interior, and then the interior skinned in aluminum. It was a challenge since the request was made after the vehicle had already been painted. We had to take extra precaution with aluminum work so we wouldn't scratch any paint on the interior bulkhead and side panels.

Due to the details in Joe’s Spyder, other potential clients slowly became new Spyder orders. We have 14 now on backlog. I sell four to six orders a month currently, with a build lead time of three to four or so months, depending on engine selection. I have made all our “options” standardized so the customers get the ideal build from the beginning.

Most of my clients aren’t very mechanically inclined or have the time to build a project. They’d rather just be able to hop in the car and drive it on the weekends.

We switched all hardware over to 316 stainless steel. We’ve also swapped out brake lines from standard VW brake lines to Formula One ni-copper alloy, above airline grade. This ensures no brake lines can get pinched. PTFE-braided stainless steel covered lines are in the required flex areas for flexibility as well as so they don’t scratch the chassis. We take pride in our details.

Our upholster does interiors for Lamborghini, Bentley, Rolls Royce, Ferrari, Land Rover, Audi, BMW, and Mercedes, so we use OEM leather/leatherette on all our interiors. We standardized dual climate-zone heated seats. Disc brakes are standard. New aluminum racing fuel cells are now standard (not used on Joe’s car), our internal cable shifters are now standard (also not on Joe’s). Standard billet CNC aluminum brake/clutch remote reservoirs, standard. Lightweight rear strut bars with integrated oil-breather box is now standard (not shown). Mil-spec wire harness standard (not on Joe’s).

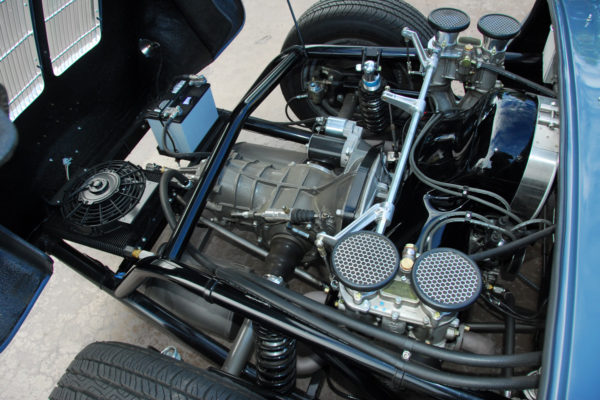

We keep re-inventing the wheel with each build and throwing in higher quality parts on all our builds. We lose profit, but would rather put a quality product on the road that will be trouble free. We include 12 month/12,000 mile warranties on our Type 1 air-cooled 160 to 200hp race engines as well as our 230hp water-cooled 2.5L race engine.

What you see on Joe’s Spyder was detail work done in a garage, our third build, done on a budget. We have now acquired a 5,000 sq ft. facility and build turnkeys for Vintage Spyders (the manufacturer of Joe’s car). Our staff has doubled, and we only use about eight percent VW parts on these Spyders, whereas they used to be about 50 percent.

We are developing a new big brake kit for our Spyders, the first zero-offset machined billed hub that will use a vented OEM Porsche rotor and Wilwood caliper, yet maintain a parking brake. They will be standardized and the price of the vehicle will not increase.

Every time we develop a new part, we do it in CAD and SolidWorks, and test strength, rigidity, moving parts, etc. We continue to develop new parts, better quality parts, and we even have been selling to competitors and they are proud to use our parts and not copy them. We CAD-engineered a new stainless steel parking brake for the Spyder and another for the Speedster, 100 percent stainless down to the hardware and internal parts.

Our new partner, RideTech builds special billet coil-overs for our builds, gassed and spring rates, adjustable ride height, and even adjustable dampening control. Also we offer a warranty on all suspension components (Bilsteins were used on Joe’s, not our new RideTech).

We are currently building some racing Spyders with RideTech Shockwave technology, using air over coil. So you can adjust ride height from your cell phone while inside the car. Handles better than coilovers. RideTech won the Optima Challenge at SEMA, using their Shockwave technology. Paired with our three-pound lightweight rear strut bar and our 230hp engine, non turbo, you’re now driving a 10-second quartermile Spyder—if you get traction!

Greg Leach of Vintage Spyders and I have partnered up and are developing a new 5-link rearend suspension for IRS transaxles. We are also developing a new front suspension for the Spyders and our newly released 356 Pre-A Bent Window coupe. They both will ride on adjustable ride height and adjustable dampening coilovers, or Shockwaves. Every component, right down to our ECU on the Subaru water-cooled engines, is set up for street/track, with idle control and race tunes.

All told, we’ve stepped out of the box with every component on our Spyders and Coupes. We will not sell or build anything basic or cheap—no used parts, all 100 percent brand new components. We have other tricks up our sleeves, but we’re not releasing any info about that yet, however.—Daniel Verwers

Comments for: A Few Words From the Builder...

comments powered by Disqus